How to customize a sheet metal panel box folding machine bending centers

Customized sheet metal panel box folding machine bending centers refers to selecting the appropriate bending position during the material bending process according to specific needs. Here are some steps and precautions for customizing a sheet metal panel box folding machine bending centers:

- Determine design requirements: Firstly, clarify the specific design requirements for the material type, size, shape, and bending angle that need to be bent.

- Analyze material properties: Understand the physical properties of the materials used, including bending strength, bending radius limitations, elastic coefficient, etc.

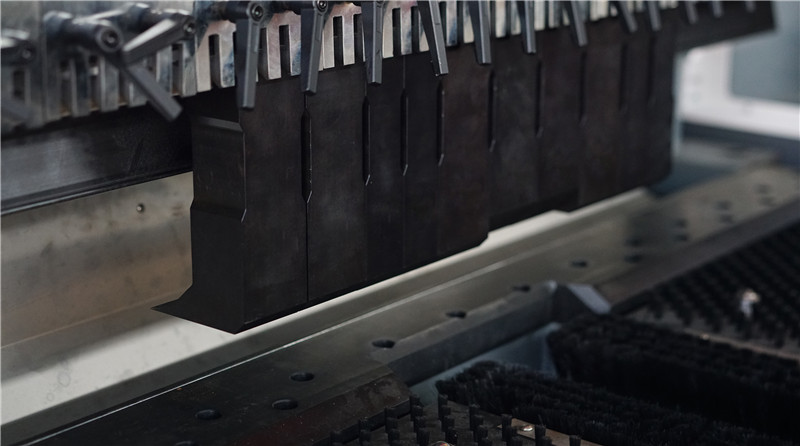

- Consider process limitations: Determine the position of the sheet metal panel box folding machine bending centersbased on the bending equipment and process requirements used. Consider the maximum bending capacity, fixation, and support methods of the equipment.

- Choose the appropriate bending process: Based on the characteristics of the material and design requirements, choose the appropriate bending process, such as pressure bending, cold bending, hot bending, etc.

- Conduct bending test: Make a sample near the selected bending position and conduct actual bending test. Through experiments, it can be verified whether the position of the sheet metal panel box folding machine bending centersis appropriate and whether it meets the design requirements.

- Consider fixtures and fixtures: Based on the bending process used and the position of the sheet metal panel box folding machine bending centers, design and manufacture corresponding fixtures and fixtures for positioning and fixing materials, ensuring the accuracy and stability of the bending process.