How to calculate and select the tonnage of pneumatic punching machinery?

How to choose the tonnage of pneumatic punching machine? F=LTσbf

L refers to the length of the trimming line. For example, if a square hole is punched, the trimming length is equal to the length of the four sides of the square hole, which is exactly its circumference.

T means that the thickness of the material is the same as the above, the unit is mm, and f is the punching coefficient, usually 1.3.

Σb refers to the tensile strength of the material of the stamped steel sheet. It is necessary to check the manual for this, and there are some on the Internet.

The effect obtained by multiplying the above several is the pressing force, but the unit is cattle, and the conversion to tons needs to be divided by 9800, and the basic tonnage is obtained.

Then, consider the quiet margin of blanking and the ejection of the material. For other things, the high-speed pneumatic punching machine divides this tonnage

by a coefficient of 0.7 to get the tonnage of the machine tool.

How to calculate the tonnage of punch machinery

Assuming that the existing ordinary hot-rolled coil has a thickness of 1.5 mm, a hole circumference of 300 mm, and a 25-ton punch machine can it be blanked?

How to calculate the required punch mechanical tonnage based on the material?

1. Calculate the tonnage of punch machinery:

Rough calculation according to Q235 material: cutting force is about 0.3*0.0015*400000000=180000N=about 18 tons;

If the material is leaked, the blank holder force is as small as possible, and 25 tons of punching machinery can be used. It is safe and reasonable to use a 35-ton punching machine.

2. Calculation of punch machinery:

Formula: Punch core circumference (mm) × sheet thickness (mm) × material shear strength (kn/mm2) = punching force (KN); converted to metric tons: divide KN by 9.81;

Punch perimeter-the sum of the lengths of all sides of any shape; material thickness-refers to the thickness of the sheet through which the punch is to be punched;

the shear strength of the material-the physical properties of the sheet, which are determined by the material of the sheet. It can be found in the materials manual.

3. Examples:

Punch holes on a 3.00mm thick mild steel sheet, square in shape and 20.00mm side length

Punch circumference=80.00mm Material thickness=3.00mm Shear strength=0.3447kn/mm2

8.00×3.00×0.3447=82.73KN; 82.73KN÷9.81=8.43 metric tons

Extended information:

1. The formula for calculating the mechanical pressure of ordinary punches:

Blanking force calculation formula: p=k*l*t*τ;

p-flat cutting force (n); t-material thickness (mm); l-punching circumference (mm); τ-material shear strength (mpa); k-safety factor, generally take k = 1.3 .

The calculation formula of punching shear force: f=s*l*440/10000;

s—the thickness of the work piece; l—the length of the work piece;

2. The design principle of punching machinery is to convert circular motion into linear motion. The main motor drives the flywheel and drives the gear, crankshaft

(or eccentric gear), connecting rod, etc. to rotate through the clutch to achieve the linear motion of the slider. The movement of the main motor to the connecting rod is a circular movement.

Between the connecting rod and the sliding block, there needs to be a transition point for circular motion and linear motion. There are roughly two mechanisms in its design,

one is ball type, the other is pin type (cylindrical type), through which circular motion Converted into linear motion of the slider. The punching machine applies pressure to the material to plastically deform it to obtain the required shape and precision;

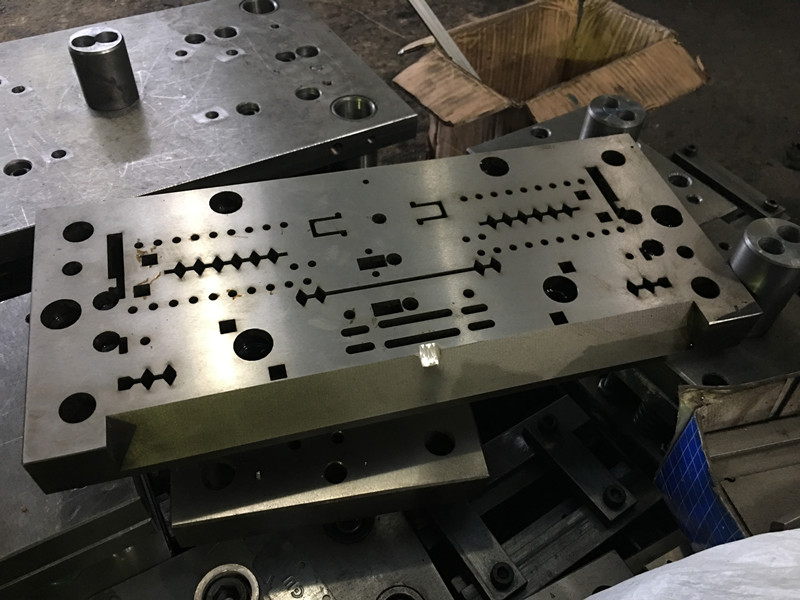

Therefore, it is necessary to cooperate with a set of molds (upper mold and lower mold), place the material in between, apply pressure by the machine to deform it,

and the reaction force caused by the force applied to the material during processing is absorbed by the mechanical body of the punching machine .