how to adjust the bending angle for the sheet metal cnc hydraulic press brake machine

Many novices did not know how to use the press brake when they first encountered it. They may just learn how to turn on and off before getting on the machine.

In fact, there are many things to know, and the equipment is still dangerous. , So you need to take protective measures yourself, check everything before starting to use,

and make sure that there are no problems before starting. There are other correct usage methods that you need to know. The editor will introduce in detail

in the following article. In addition, before bending the sheet, you need to make sure that the bending angle meets the standard. If it is not standard, you need to adjust the angle.

The following editor will introduce you to how to adjust the bending angle.

How to operate the bending machine sheet metal cnc hydraulic press brake machine correctly? The following is a detailed tutorial, please understand.

1. Strictly abide by the safe operation regulations of bending machine workers, and wear labor protection equipment according to the regulations.

Before starting, you must carefully check whether the motor, switch, circuit and grounding are normal and firm, and check that the control parts and buttons

of the equipment are stuck in the correct position.

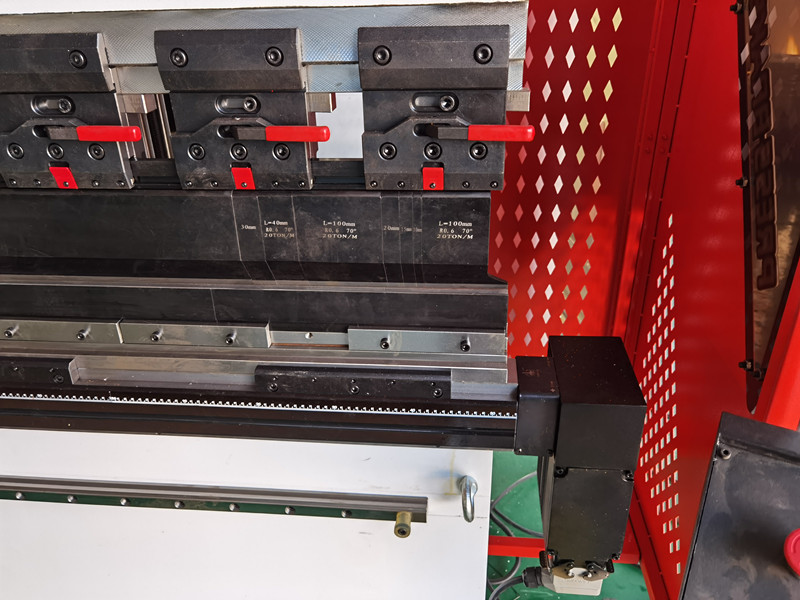

2. Check the overlap and firmness of the upper and lower molds. Check whether each positioning device meets the requirements of being processed.

When the upper sliding plate and each positioning axis are not at the origin, run the return-to-origin program.

3. After starting the equipment, run it idling for 1-2 minutes, and move on the sliding board 2-3 times at full stroke. If there is any abnormal

sound or malfunction, stop immediately, troubleshoot the malfunction, and work after everything is normal. When working, one person should be in a

unified command, so that the operator and the feeding and suppressing personnel should cooperate closely to ensure that the cooperating personnel

are in a safe position before issuing the bending signal.

4. The sheet material must be compacted when bending, to prevent the sheet material from lifting up and hurting people during bending.

The power supply must be cut off when adjusting the sheet metal die, and the operation should be stopped. When changing the opening of the

variable lower mold, no material is allowed to come into contact with the lower mold. When working, no one is allowed to stand behind the press brake.

It is strictly forbidden to fold the sheet at one end alone.

How to adjust the bending angle of the bending machine sheet metal cnc hydraulic press brake machine?

Before using the bending machine to bend the material, you need to adjust its various angles, including the bending force, the distance of the back gauge,

the upper limit of the slider, the speed of the slider, and the adjustment of the upper and lower mold gaps, etc., to make it reach Actual operation requirements.

How to adjust these parameters? The following is a detailed introduction:

1. The adjustment of the angle of the bending machine sheet metal cnc hydraulic press brake machine is mainly to calculate the kN value of the

bending force of the sheet metal according to the calculation formula,

and calculate the value of the indicated pressure P according to Table 1, and then adjust the handwheel of the overflow valve to make the force generated

Slightly larger than the kN value of the folded plate.

2. The adjustment of the back gauge distance of the bending machine needs to be used for positioning in the length direction when bending the sheet.

The button on the front button box controls the motor adjustment, and the adjustment value can be from the revolution table on the button box. Read out,

the conversion value of the revolution table is 0.1mm/revolution, and there is a handwheel for fine adjustment.

3. The adjustment of the upper limit of the slider of the bending machine needs to be realized by adjusting the position of the striker Ⅱ, so that the rising

slider can stay at the required top dead center position, which can shorten the stroke distance of the slider and reduce the working cycle time. Thereby increasing productivity.

4. The adjustment of the slow motion of the slider is related to the impact block I. Touch the stroke switch to make the slide slow motion, and the length

of the slow stroke time is adjusted by the adjustable potentiometer.

5. The adjustment of the gap between the upper and lower molds in the bending machine is completed by the button on the button box at the bottom right

of the operating workbench. Operate in the direction indicated by the label of the bending machine. The initial adjustment gap should be greater than the

thickness of the plate, depending on the workpiece. The size of the angle to trim the gap.

6. Of course, the handwheel can also be used for fine adjustment. The adjustment value is displayed by the calculator. Each increase or decrease of a single digit is 0.1mm.

The important thing to use a bending machine is to know how to use it correctly. I believe you will already know after reading the above introduction.

After knowing the correct use method, you can adjust the bending angle. I hope you can refer to the above content.