Hand Fiber Laser Welding Machine Development and Application for good welding advantages

Hand Laser Welding Machine Promotes The Development and Application of Titanium Alloy

With the development of science and technology and the demand of the market, the original status of many metal products is constantly declining,

which is gradually replaced by titanium alloy, because titanium alloy is often used in parts, machinery and other fields, so laser welding machine is needed to repair and weld.

Laser welding machine technology has become more mature, compared with the traditional mechanical repair technology, not only more efficient, due to the size of parts,

material constraints are smaller, but also in the use of the cost has been greatly reduced, laser welding machine for titanium alloy welding has been greatly improved,

large to large mechanical titanium alloy equipment, small to very small titanium alloy process products, but also can be highly efficient, high-speed processing of its products,

basically because of the shape of the required welding, complex impact. Titanium alloy material has its own strength and corrosion resistance.

the attention of various industries, laser welding machine technology will be widely used in various industries, play a more and more important role.

Hand Laser Welding Machine Promotes The Development and Application of Titanium Alloy

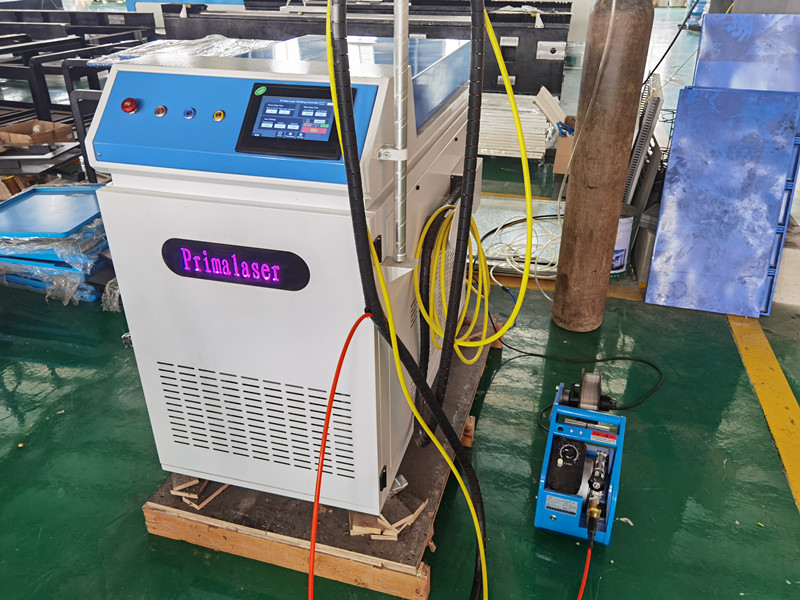

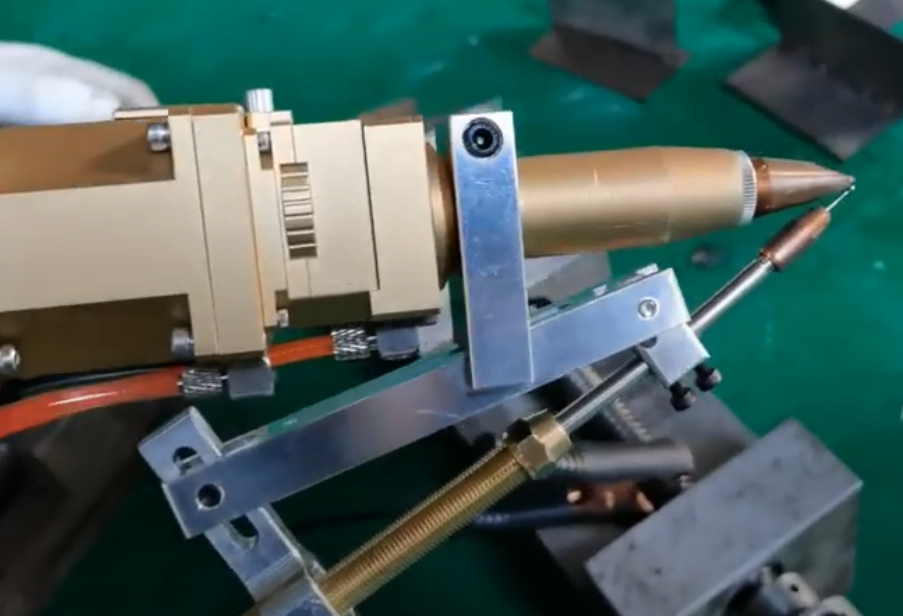

Primalaser portable hand laser welding machine is also widely sold and used due to its good performance,

it is really a new technology, so many former customers buy it from Primalaser and use it in their daily production .

★High energy density, low heat input, small amount of thermal deformation, and narrow melting depth in the heat and heat affected zone of the melting zone.

★The cooling rate is high, so that the weld structure can be fine and the joint performance is good.

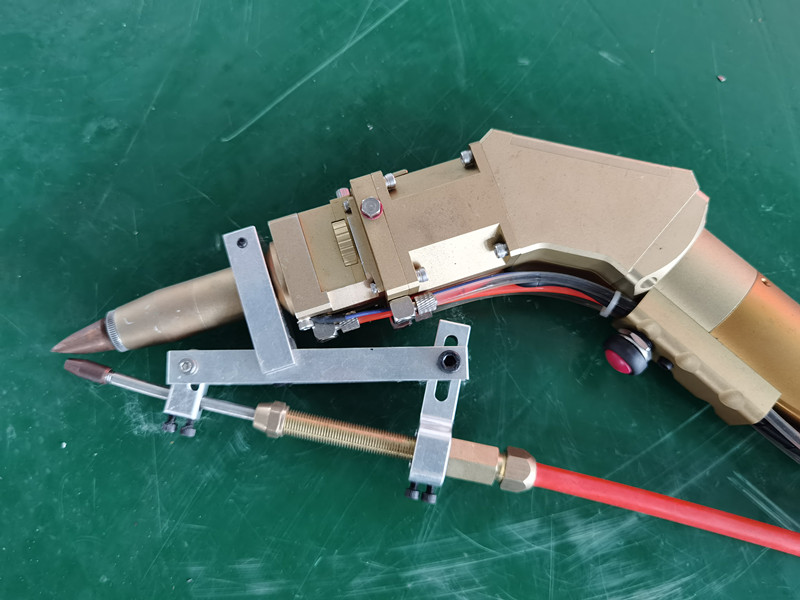

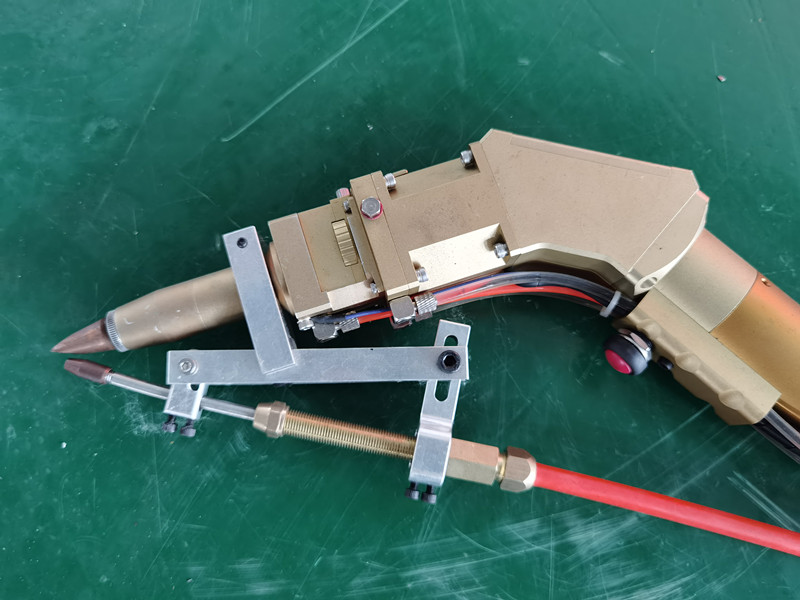

★ Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly improving work efficiency.

★The weld is fine, the penetration is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

★ No consumables, small size, flexible processing, low operating and maintenance costs

★The laser is transmitted through the optical fiber and can work with the assembly line or the robot.

Product advantages:

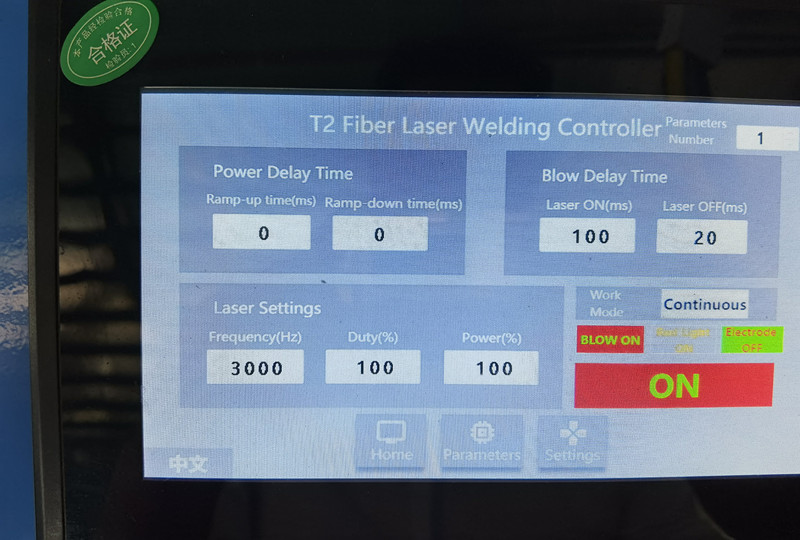

The laser welding machine adopts 150-3000 watt fiber laser source, which has high photoelectric conversion efficiency and long life of 100,000 hours.

The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times that of YAG laser.