Global Laser Cutting Machine Has Been Positive Toward Improved Automation And Intelligent Direction

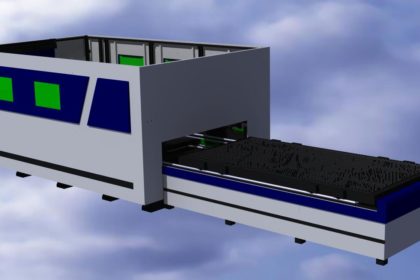

Laser cutting machine industry rapid advances in stimulating economic development has evolved from ancillary products for the real product. While inspired by technological progress, the global laser cutting machine has been positive towards automation and intelligent direction improvement. However, China’s domestic laser cutting machine industry level is still in the primary stage, so our laser cutting machine industry need to follow the world trend to enter the high-end market.

China laser cutting machine started late, after ten years of development, China laser cutting machine has become one of the top ten industries in the machinery industry, the rapid development of China’s sheet metal industry to provide a strong guarantee, some laser cutting machine to fill the domestic blank, has been able to meet the needs of the domestic market, some products are exported. Since joining the WTO, and China has made considerable progress, enhance the level of laser cutting machine is very fast, with the world advanced level in the gap is gradually narrowing. With China’s increasingly open China laser cutting machine will also further open the international market.

Briefly talk about laser cutting machine works: in the course of processing, the material to be processed after irradiation will form a pit in the center, then work stream will be quickly removed and the cladding material to form a hole. This is similar to cut hole threading hole, the laser will be cut along the starting point for the processing of such holes, cutting contours are designed by a computer program that can be very precise alignment.

Then we will see the number at the start of laser cut perforations to cut into the contour of this hard, cutting velocity vector in the direction of a great change is in the direction of 90 ° vector rotation by the tangential direction of rotation perpendicular to the cutting contour cutting the contour, the contour angle is 0 °. Cutting surface of the workpiece so that the flow of rough cutting surface, mainly in a short time so that the laser beam is moved rapidly in the direction of the vector.