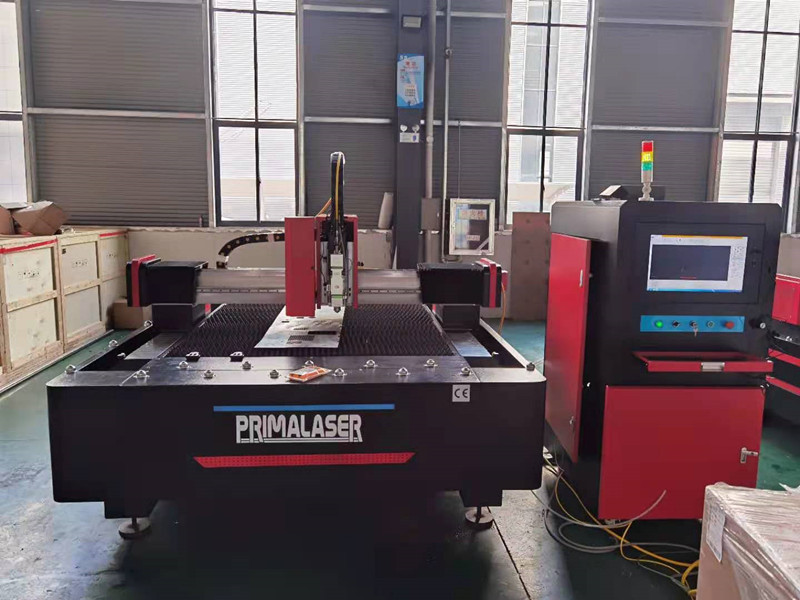

Explanation of the main composition and configuration of metal iron fiber laser cutting machine

The role of each part of the fiber laser cutting machine: The cutting speed, precision, and flexibility of the fiber laser cutting machine has attracted wide attention

from the industry. Compared with other laser cutting machines on the market, the fiber laser cutting machine is used in thin plate cutting. Occupy a greater

cutting advantage. The fiber laser cutting machine can perform high-precision and precise cutting of various thin metal materials. It can be used for plane cutting

or bevel cutting, and the cutting surface is flat, smooth and free of burrs. It is widely used in the field of manufacturing and processing. Fiber laser cutting machine

is currently one of the most advanced technologies in the world. As users, we should learn more about the functions of each part of the fiber laser cutting machine

in order to better use the fiber laser cutting machine.

Laser: Everyone knows: Laser plays a very important role in fiber laser cutting machine. It is the key and core technology of fiber laser cutting machine, and it is

responsible for the performance of the whole machine structure and scheme as well as the cutting effect. The fiber laser cutting machine achieves the cutting effect

by focusing the high-density laser beam emitted by the laser on the workpiece.

Cutting head: The cutting head is one of the important parts that determine the cutting accuracy of the laser cutting machine. Choosing a suitable cutting head can

achieve a more precise cutting effect.

Numerical control system: realize the linkage control of the X, Y, Z axis of the laser cutting machine table and the laser power system control. It also controls the

output power of the laser.

The main machine part of the machine tool: the machine part of the laser cutting machine, the mechanical part that realizes the movement of the X, Y, and Z axes,

including the cutting work platform. It is used to place the workpiece to be cut and can move it correctly and accurately according to the control program, usually driven by a servo motor.

External light path: Refractive mirror, used to guide the laser in the required direction. In order to prevent the beam path from malfunctioning, all mirrors

must be protected by a protective cover, and a clean positive pressure protective gas should be introduced to protect the lens from contamination.

Stabilized power supply: connected between the laser, CNC machine tool and the power supply system. Mainly play a role in preventing interference from external power grids.

Operating table: used to control the working process of the entire cutting device.

Water chiller: used to cool the laser generator. The cooling water takes away the excess heat to keep the laser generator working normally. The chiller also cools the

external light path reflector and focusing mirror of the machine tool to ensure stable beam transmission quality and effectively prevent the lens from being

deformed or broken due to excessive temperature.

Air compressor, air storage tank: provide and store compressed air.

Air cooling dryer, filter: used to supply clean and dry air to the laser generator and beam path to maintain the normal operation of the path and reflector.