Difference between a torsion shaft synchronous press brake and electro-hydraulic servo CNC press brake Bending Machine?

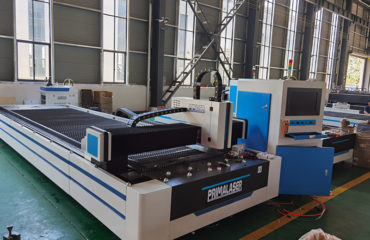

The technical field of synchronous CNC press brake Bending Machine with torsion shaft, in particular, relates to a synchronous device with torsion shaft of press brake Bending Machine. The synchronous device with torsion shaft includes a synchronous torsion shaft, a swing arm connected with both ends of the synchronous torsion shaft and a connecting rod connected with the swing arm. One end of the swing arm is movably connected with the synchronous torsion shaft, the other end of the swing arm is movably connected with the connecting rod, and the bottom end of the connecting rod is provided with a swing arm pier, The lower part of the swing arm pier is provided with a slider reinforcing rib, which is arranged at the inner side of the slider and supports the slider. Both ends of the synchronous torsion shaft can move synchronously, so that both ends of the slider can move up and down synchronously, meeting the requirements of its balance. The torsion shaft servo press brake Bending Machine has the characteristics of reasonable design, simple assembly and adjustment, simple parts processing, and improved product quality.

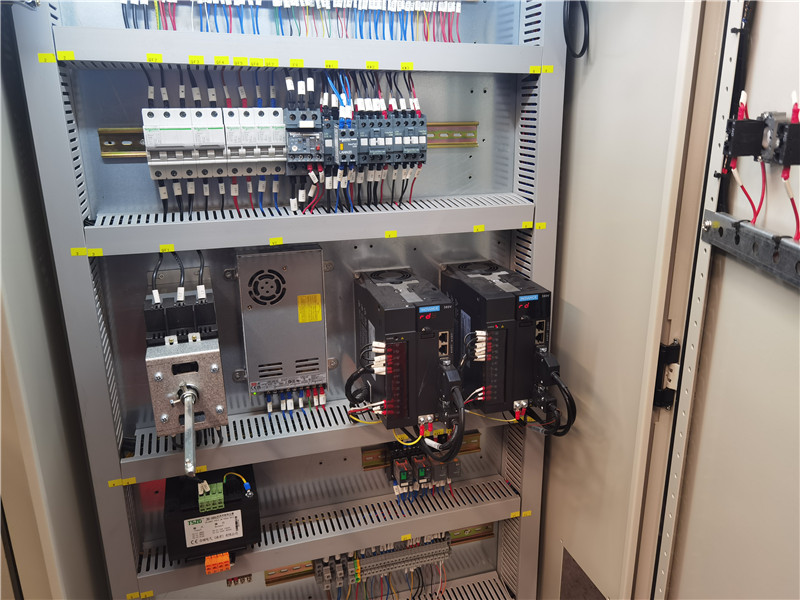

No special measures are required for the return (rising) stroke of the electrohydraulic servo CNC press brake Bending Machine. In the fast forward stage of descending stroke, on the basis of parallel synchronization, two one-way throttle valves are used to eliminate the deviation caused by manufacturing quality, leakage and other factors, so as to ensure descending with a certain synchronization accuracy. When entering the process stage but not contacting the workpiece, further synchronous correction shall be made by the two deviation correction piston cylinders installed on the workbench. Assume that one side contacts with the deflection correcting plunger first, and the larger deflection correcting force will slow down or stop the movement of that side until the other side catches up and contacts the hydraulic and pneumatic plugs of the deflection correcting plunger at the same time. The deviation correction force can be set by the overflow valve and read by the pressure gauge. The practice shows that the synchronization effect is very obvious, because various asynchronous factors can be ignored compared with the correction force. In order to make full use of the machine’s capacity, the overflow valve 3 should be unloaded after a period of time.

- Primapress thinks that the biggest difference is that the structures of the two sides of the bending slider to ensure synchronization are different. The torsion shaft is synchronized by connecting the rigid shaft of the two cylinder pistons at the same time, and the electro-hydraulic servo is synchronized by the servo synchronization valves on both sides.

- The electro-hydraulic servo system has high synchronization accuracy, real-time error feedback, and strong anti deflection load capacity of the bending slider; The synchronous precision of the torsion shaft synchronous press brake Bending Machineis low, there is no error feedback, and the anti deflection load capacity of the bending slider is poor.

- The hydraulic control system of electro-hydraulic servo press brake Bending Machineis more complex than that of torsion shaft synchronous press brake Bending Machine, and the overall price is also high.

One is to adjust the stroke of oil cylinder mechanically, and the other is to control the stroke by hydraulic pressure. The torsion shaft is synchronized by the balance shaft, and the electro-hydraulic servo is synchronized by the servo synchronization valves on both sides.