What is the difference between a dual servo drive CNC bending machine and an ordinary single servo drive hydraulic bending machine?

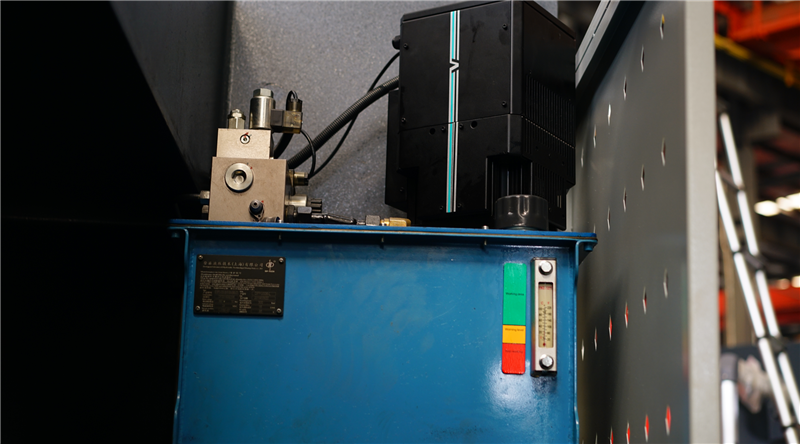

The double servo motor drives the bending machine, which is driven by double servo motors and double oil pumps. The ordinary single servo drive bending machine has only one main servo motor and one oil pump.

Double servo motor driven bending machine adopts oil pump to control hydraulic oil, single servo motor drive adopts solenoid valve control.

What are the advantages of dual servo motor driven CNC bending machine?

1. Good working environment, power saving and energy saving

The machine is driven by servo motor, no noise and 50% energy saving.

2. The hydraulic components have a long service life, no oil leakage, no need to worry about the oil overheating, and more fuel-efficient

The pump control technology replaces the traditional valve control technology, eliminates the throttling loss, has no overflow loss, and has a significant energy saving effect. The oil cylinder capacity is reduced by 70%, and the oil temperature and oil pressure are reduced by 10% compared with the traditional bending machine.

3.Fast working speed, processing efficiency increased by 30%

The response frequency of the servo motor is higher than that of the proportional solenoid valve. Therefore, the bending speed of the double-servo pump-controlled bending machine is faster than that of the traditional electro-hydraulic bending machine.