Development status and advantages of metal coil laser cutting blanking production line

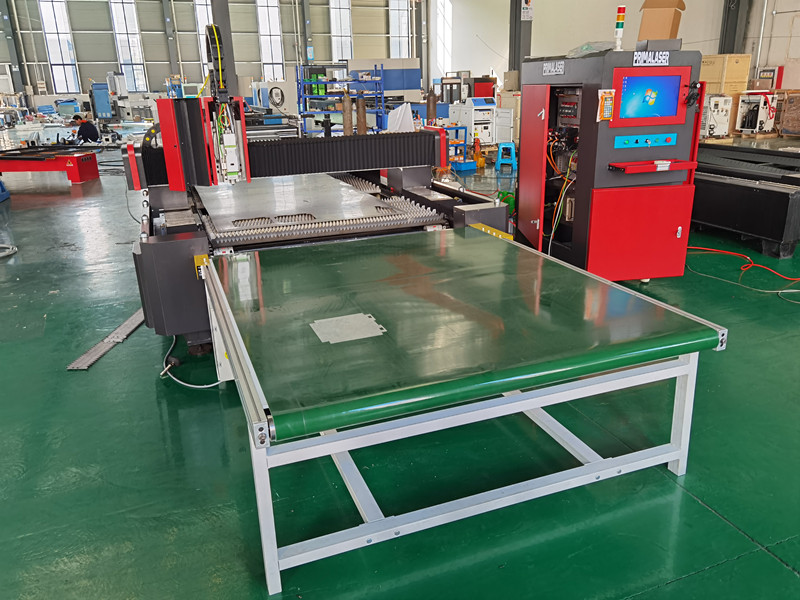

In the current industrial production and manufacturing, in order to facilitate storage and transportation, the plates are all harvested coils. During production and use, the metal coil is uncoiled and leveled and then sent to the laser cutting machine. The metal coil laser cutting production line is mainly composed of CAD/CAM programming system, automatic uncoiling, leveling system, servo automatic feeding, and laser cutting system. It can realize automatic production, greatly improve production efficiency, reduce labor burden, and reduce production costs. It has the characteristics of high efficiency, high precision and convenient operation.

In recent years, due to the strong characteristics and advantages of the metal coil laser cutting production line, some domestic companies have also set off a wave of metal coil laser cutting production lines. Although there are still technical deficiencies compared with well-known foreign companies, over time, Over the course of the process, the degree of internationalization continues to increase, and the manufacturing system continues to mature, and the gap between laser technology and enterprises in developed countries has been significantly reduced.

01

Advantages of practical application of metal coil laser cutting blanking production line

1) Continuous cutting production and high equipment utilization. After the metal coil is uncoiled and leveled, it is fed by the feeder to the top of the laser cutting machine’s rotating worktable for cutting. With the movement of the worktable, the process of cutting while feeding can be realized, effectively shortening the cutting time of parts and improving the equipment Use efficiency.

2) Production is flexible. It can respond to the needs of production changes at any time. When the required parts change, the two-dimensional graphics can be modified through the programming software to cut the required parts. There is no need to change the hardware structure of the equipment, and it has the flexibility to manufacture different products.

3) With automatic typesetting function, reduce the generation of excess waste. The cutting host system itself has the function of automatic typesetting, and it can mix and produce at any time according to the spare parts needed temporarily. The required parts are simulated and automatically arranged on the computer to effectively reduce the generation of waste and reduce production costs.

4) The processing cost is low. The production process is automated, which effectively reduces labor costs. Laser cutting itself has fewer consumables and high material utilization, which further reduces the cost of the entire production line.

02

Technical characteristics

1) The CNC laser cutting machine adopts a professional system to control the synchronization of the motors. The cutting machine table is a crawler cutting table, and the crawler type is equipped with a needle plate cutting strip. During processing, the cutting table is synchronized with the uncoiling servo feeding and runs at the same speed. Realize the cutting of metal coils and plates. It is suitable for the processing of metal metal coils within 3mm, the repeat positioning accuracy can reach ±0.03mm, and the positioning accuracy is within ±0.05mm/m.

2) The body of the CNC laser cutting machine adopts a steel plate welding structure, and has been tempered at high temperature to completely eliminate welding stress. When machining, a CNC gantry milling machine is used to process the guide rails and rack mounting surfaces on both sides of the bed at one time to ensure the consistency of the precision of the guide rails and rack mounting surfaces on both sides of the frame.

3) The straightening wheel of the leveling machine is made of bearing steel, and the surface is thickened and electroplated, which is durable and wear-resistant. The operation is simple and convenient. All the correction wheels are driven by gears and equipped with a pressure roller, which effectively enhances the rigidity of the correction wheels and improves the correction quality.

In summary, the metal coil laser cutting production line is an advanced manufacturing technology with CNC technology as the core and a combination of computer technology, communication technology and database management technology. It is suitable for the production of large quantities of parts.