Components and functions of the actuating mechanism of the plate metal hydraulic shearing machine

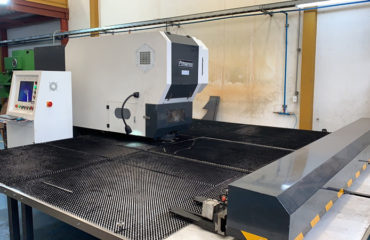

Plate shears (English name: plate shears; guillotine shears) is a machine that uses one blade to make reciprocating linear motion relative to the other blade to cut plates. With the help of a moving upper blade and a fixed lower blade, a reasonable blade gap is used to apply shear force to metal plates of various thicknesses, so that the plates can be broken and separated according to the required size. Plate metal hydraulic shearing machine belongs to one of the forging machines, which is mainly used in the metal processing industry. The products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration and other industries to provide required special machinery and complete sets of equipment.

The conveying mechanism of the plate metal hydraulic shearing machine is mainly used to convert the torque output by the engine into the power of the roller to transport the sheet metal. The belt pulley transmission is mainly used in this process. Because its transmission ratio is easy to control, and the conveying sheet metal is light, the required transmission torque is not very large, so the scheme is to use the belt pulley transmission. Because it needs intermittent mechanism, a pair of incomplete gear transmission is added in the transmission to realize intermittent transmission of the mechanism.

The two main parts of the actuator are the planetary gear and the six bar mechanism. The six bar mechanism needs to carry out trial calculation first to determine the length of each bar, and at the same time meet the requirements for the length of the crank rocker mechanism. Then calculate the transmission angle, and adjust the length of each bar through the size of the transmission angle. The length of each link of the six bar mechanism is determined. Brief description of the connection between the conveying mechanism and the actuator: to make the conveying mechanism and the actuator meet the requirements exactly, it is necessary to make the incomplete gear at the center of the locking arc during installation, just in time for the cutter to finish cutting the sheet metal.

Safety precautions during the use of the shear:

(1) Before work, carefully check whether all parts of the trigger are normal, whether the electrical equipment is in good condition, whether the safety protection device is reliable, and whether the lubrication system is unblocked. Then add lubricating oil, test run, and steam cutting are in good condition before use. When two or more people are working together, one person must be determined to give unified command, and the machine tool can only be started to cut materials when the table top and its surroundings are checked to be free of obstacles. The plate shears are not allowed to cut two kinds of plates with different specifications and materials at the same time. It is prohibited to cut without material. The surface of the cut plate shall be flat. It is not allowed to cut narrow plates that cannot be compressed.

(2) Concentrate when operating the plate shears, and keep your fingers away from the knife edge by 200mm and the pressing device when feeding. The feeding and reclaiming shall prevent the steel plate from being scratched and the steel plate from being cut off and hurting people. The foot switch shall be equipped with a solid protective cover plate to prevent heavy objects from falling onto the foot switch or stepping on it by mistake.

(3) The knife edge clearance of various shears shall be properly adjusted according to the specified thickness of the shears to prevent accidents caused by improper use.

(4) The brake of the plate metal hydraulic shearing machine shall be checked regularly to ensure reliability and prevent the upper knife edge from falling down suddenly to hurt people due to the loosening of the brake.

(5) The edges of the sheet and the cut strip are sharp and sometimes have burrs, so scratches should be prevented.

(6) In the process of operation, safe hand tools are used to complete operations such as feeding, positioning, taking pieces and clearing leftovers to prevent fingers from being crushed by the mold.