Characteristics and maintenance methods of hydraulic ironworker combined punching and shearing machine

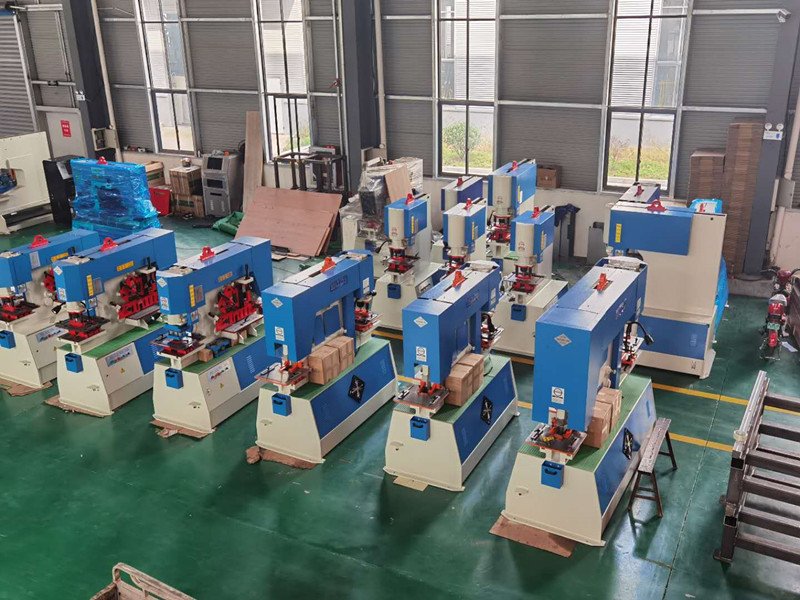

hydraulic ironworker combined punching and shearing machine is a kind of sheet metal and profile processing equipment. It is widely used in the manufacture of steel structure processing, signal towers, TV broadcasting towers, telecommunication towers, street lamps, elevators, ventilation pipes and other related enterprises. It can be said that the hydraulic ironworker combined punching and shearing machine is a kind of equipment that integrates various functions. The hydraulic ironworker combined punching and shearing machine itself has many characteristics. Below we will briefly introduce the relevant characteristics of the hydraulic ironworker combined punching and shearing machine.

- It works in hydraulic mode. The hydraulic ironworker combined punching and shearing machinehas a reasonable structure design, light weight, low noise, convenient operation and high work efficiency.

- Each station of the hydraulic ironworker combined punching and shearing machineis designed and assembled with the standard configuration adopted. And these workstations and dual hydraulic workstations can work independently at the same time without affecting each other, and can work efficiently and orderly.

- The machine is processed by the world’s technology. As far as the body is concerned, it has a good welding fit, is sturdy and durable, has good wear resistance, and has a long service life. It can be used by us for a long time, thereby saving economic costs.

All devices have an application period, so if you are willing to make the application period of this device longer than expected, or you are willing to make the device less easily damaged than imagined, then what you can do is standard practice. Operation, that is to say, do a good job in clearing the equipment, so that can improve the service life of the equipment. Then it may be the same for the hydraulic ironworker combined punching and shearing machine. It is necessary to do a good job in the quality assurance and environmental sanitation of the hydraulic ironworker combined punching and shearing machine every day, and then you will see that the application time of this equipment is longer than you want to. Then the most important point to improve the service life of the punching and shearing machine is to actually operate it according to the instructions for use of this equipment. That is to improve the service life of the hydraulic ironworker combined punching and shearing machine, and this is still important. The hydraulic ironworker combined punching and shearing machine is “oiled” regularly, which means that some areas must be filled with some oil every time, and this equipment is rusted. Because of the rust, it is very easy to make this A device has become less flexible.

In other words, it is important to check whether the household appliances are safe and reliable, so that everyone can operate safely. This is an important factor that will endanger the service life of the hydraulic ironworker combined punching and shearing machine. The other one is that the power switch and other areas of the equipment are often checked to see if there is any damage.

Maintenance method of multifunctional hydraulic ironworker combined punching and shearing machine

Hydraulic hydraulic ironworker combined punching and shearing machine is a sheet metal and profile processing equipment integrating various functions. , It can cut, angle, punch, bend, etc. on flat plate, round steel, square steel, angle iron, channel steel, I-beam, etc. It has the characteristics of low noise, safe operation, low cost of use and high processing efficiency. Widely used in steel structure processing and production, high-voltage wire towers, telecommunication towers, street lamps, advertising, shelves, elevators, ventilation ducts and other civil facilities production enterprises; and can be used in large steel structure bridges, military, aerospace and other high-demand, high-precision and other production construction.

The bed of the machine consists of fuselage, machine base, section steel bracket, angle steel bracket, and shearing table. The fuselage and the base are welded by steel plates, and the others are connected by bolts, which not only ensures the strength and rigidity during work, but also ensures the convenience of maintenance, assembly and disassembly. The right wall plate of the bed is provided with an adjustable pad to limit the left and right movement of the blade, and the angle steel bracket is provided with an adjustable pressing device to press the angle steel for shearing. The section steel bracket is provided with square holes and round holes of different sizes, so that the square steel and round steel can pass through smoothly and perform shearing. There is an adjustable pressing plate on the cutting table, which can be adjusted according to the thickness of the workpiece to be sheared. There is an adjustable stop on the table for positioning and shearing. The block can be adjusted at any angle, and the flat steel or angle steel can be sheared at any angle by its side positioning

The difference between a bending shearing machine and a CNC bending machine mold and a traditional CNC bending machine mold with a movable knife mold clamp is that a movable knife mold clamp is installed on the sliding upper beam, and a movable knife mold clamp is installed on the movable mold clamp at the same time. A bending die and a shearing knife or two kinds of bending dies are installed at the same time, and a bending die and a shearing knife are installed on the movable die clamp; The mold is called CNC bending machine mold.