Basic knowledge and operation precautions of sheet metal CNC shearing machine

The sheet metal CNC shearing machine is generally controlled by a general-purpose or special-purpose computer to realize digital program control. It usually controls mechanical quantities such as position, angle, speed, and switching quantities related to the flow of mechanical energy. The production of CNC shears depends on the appearance of data carriers and binary data operations.

The performance characteristics of sheet metal CNC shearing machine:

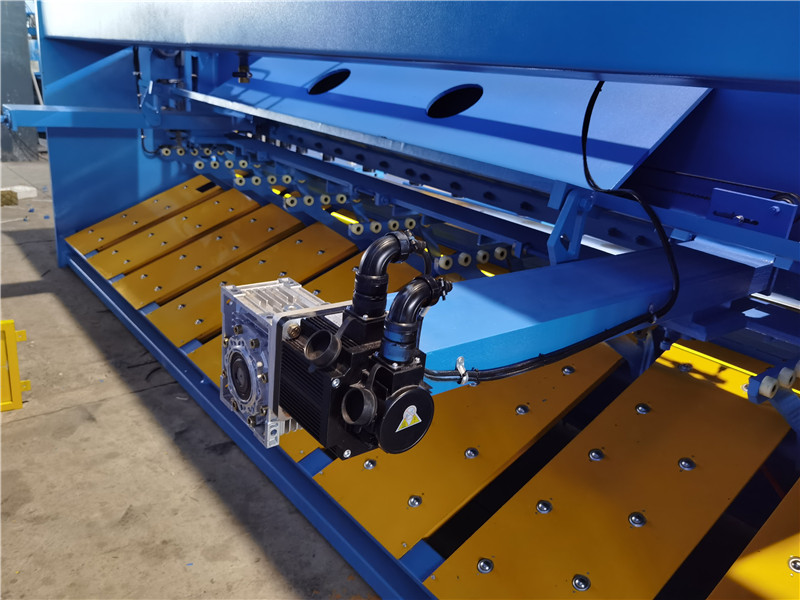

- Accurate forced positioning, worm gear and worm drive, concentric polished rod screw, no noise structure, steel plate welding structure, hydraulic transmission, accumulator return, easy operation, reliable performance, beautiful appearance. Light and fast.

- It is equipped with a light alignment device, and can steplessly adjust the stroke of the upper tool rest (optional), and adopts a fence-type personal safety protection device.

- The size of the back gauge and the number of cuts have a digital display device, hydraulic transmission, and a pendulum knife holder. The overall welding of the frame is sturdy and durable, and the return stroke of the accumulator cylinder is used, which is stable and fast.

- It has the function of infinitely adjusting the stroke. The gap between the upper and lower blades is adjusted with the handle, and the uniformity of the blade gap is easy to adjust. Guards and electrical interlocks ensure safe operation.

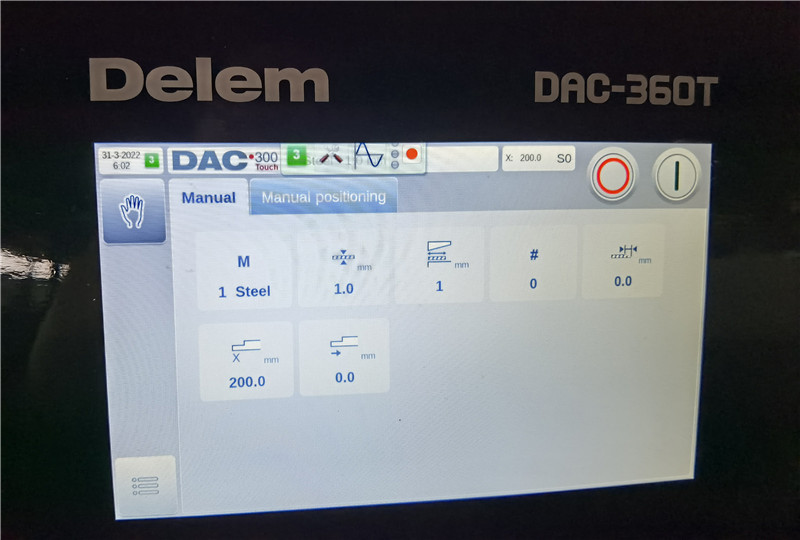

- The CNC numerical control system and the position encoder form a closed-loop control system, which has fast speed, high precision and good stability, and can accurately ensure the dimensional accuracy of the back gauge displacement. At the same time, the numerical control system has various additional functions such as compensation function and automatic detection.

Precautions for the operation of sheet metal CNC shearing machine

CNC shears are very important for today’s era of technological development. From the perspective of improving work efficiency, many large and medium-sized enterprises have seen the dawn in the production of finished products due to the emergence of shearing machines. The production workshop no longer has to worry about the supply and demand of its own products in the market, and has played a great role in processing such as metal and non-metallic sheets. In addition, the shearing machine is also useful for fast shearing of some plates that need to be processed. For example, the traditional method of cutting wood is mostly the method of sawing. Everyone knows the sawing method. The slow speed also makes people feel hard and tiring, and it is particularly inconvenient to use, and sometimes the saw blade is very easy to wear and break.

However, the feeling of using sheet metal CNC shearing machine equipment is different, the aging is fast, it is easy and simple, and the quality of the cut material is very high. Because the height of the shearing machine has two blades merged into a joint, and the cutting joint can be adjusted on the operation button, it can be cut in place at any angle, even if the plate is bent and deformed, adjust The ratio of the upper and lower blades on a good shearing board can be cut according to the size of the product, and can be used freely to achieve the purpose.

There are several important details that need to be paid attention to during the operation of the sheet metal CNC shearing machine. Before each start-up, the power-on circuit of the machine and the power supply of the lower shearing machine should be checked to see if the circuit is aging due to long-term use, and check whether the circuit is damaged or not. Rats and other animals bite off. Once it is not connected well due to wiring problems, etc., it is easy to burn out the shearing machine during use. Secondly, there are many buttons on the shearing machine, which is also an important issue for inspection and maintenance, because when the staff uses the shearing machine, the buttons inside are often used in the process of producing finished products. We know that anything that is used too much and is used for a long time will be aged and easily damaged, so the buttons are also the objects to be checked frequently. If the buttons are easy to sway, they should be replaced in time. Of course, if the shearing machine is often maintained during use, the sheet metal CNC shearing machine is very durable.