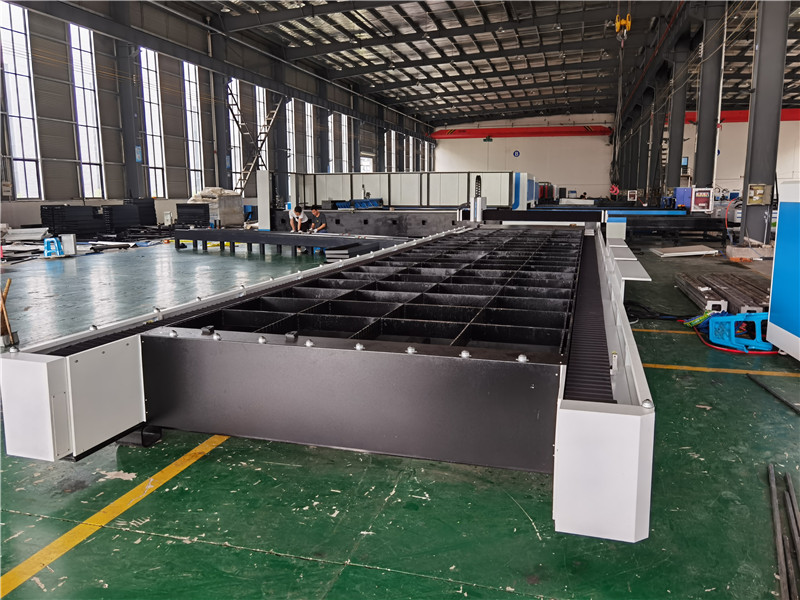

Advantages, characteristics and application development of large worktable high power metal laser cutting machine

Metal laser cutting machines are constantly developing in the direction of high-power, large-format, and thick plates. With the development of major projects such as road construction, railway construction, hydropower construction, water conservancy construction, energy construction, mining construction, construction industry, etc., the traditional cutting methods used in my country for metal materials are as follows: flame cutting, plasma cutting, cutting accuracy and speed To a large extent, it is limited, especially for large thick plate cutting, the more traditional cutting speed of cutting equipment, high precision, and perfect cutting effect, so many thick metal plate manufacturers will continue to explore the market that can meet the requirements of cutting equipment. demand.

As the industry becomes more and more widely used, the materials being processed are getting bigger and bigger, and the large-format laser cutting machine came into being. It is mainly suitable for sheet metal processing, advertising, kitchenware, lamps, knives, hardware and other industries. In recent years, with the continuous increase of my country’s large-scale infrastructure construction, the field of cutting equipment is very hot.

Advantages, characteristics and application development of large-format metal laser cutting machine

1.The advantages of large-format laser cutting machine

The slit is narrow, the accuracy is high, and the slit roughness is good, and there is no need to process after cutting. The laser has a high degree of automation,

can be completely enclosed for processing, has no pollution, and has low noise, which greatly improves the working environment of the operator.

Lower processing costs. One-time equipment investment is more expensive, but continuous, heavy processing will ultimately reduce the processing cost of each part.

The laser is contact-free processing, with low inertia and fast processing speed. It is time-saving and convenient to program with the CNC system CAD/CAM software,

and the overall efficiency is very high. The high energy density of the laser is enough to melt any metal, and it is especially suitable for processing some materials

that are difficult to process by other means of high hardness, high brittleness, and high melting point. Laser processing has the advantages of high energy density,

short action time, small heat-affected area, small thermal deformation, and small thermal stress. In addition, the laser is non-mechanical contact processing and

has no mechanical stress effect on the workpiece. Suitable for precision machining. The laser processing system itself is a computer system, which can be

easily arranged and modified, and is suitable for individualized processing.

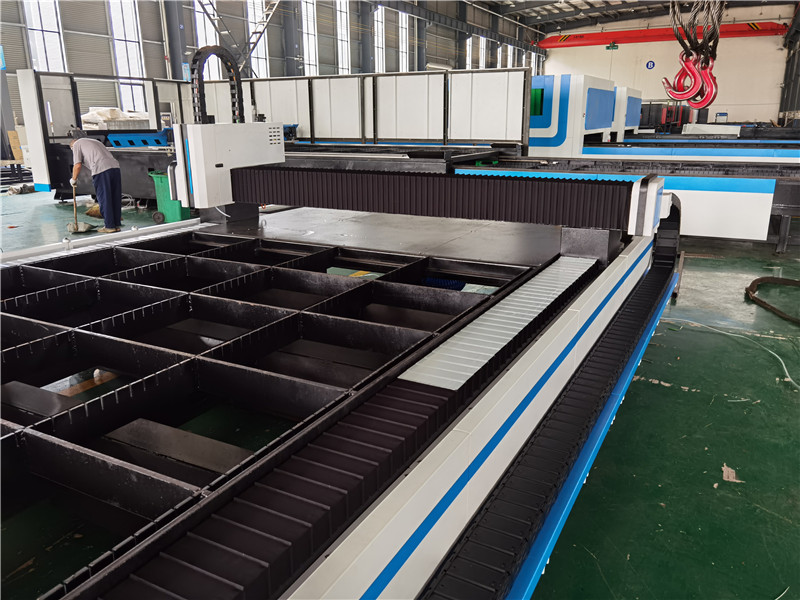

Second, the main features of large-format laser cutting machine

The cutting precision is high, the stability is good, it can meet the precision machining of the parts, and the dynamic performance is stable, and it can work for a long time.

The quality of the cutting section is good, so that the cut is flat and smooth, and the section does not need post-processing, which is suitable for cutting flat or flat plates.

The cutting size is large, suitable for cutting materials. The processing materials are: ordinary carbon steel, stainless steel, alloy steel, aluminum plate, copper plate,

titanium plate, etc. High cost performance: It can replace CO2 laser cutting machine, CNC punching machine, and shearing machine for sheet metal cutting.

The cutting speed is fast and the efficiency is high.

The third is the application and development of large-format laser cutting machines

With the continuous development of my country’s ocean shipping, military ships and outdoor large-scale commercial activities, the manufacturing

demand for large ships, large equipment and large plates is strong. At present, my country’s steel plate cutting generally uses flame cutting and plasma cutting.

Due to limited accuracy, especially for the manufacture of materials with high requirements for special materials such as decks and hulls, general cutting equipment

can no longer meet the higher manufacturing requirements. Therefore, the market urgently needs new cutting equipment with higher performance technology.

Many large-scale foreign equipment manufacturers generally use large-format fiber laser cutting machines for manufacturing. Domestic companies have also begun to replace equipment, especially for special-purpose sheet metal processing. Laser cutting has become a necessary means of processing. It is expected that in the next 5-10 years, the market

will have greater demand for the production of large-format laser cutting machines.

In summary, due to the advantages and processing characteristics of large-format metal laser cutting machines, it is more suitable for the manufacturing and

processing of modern large ships, large equipment and large plates. With the development of ocean transportation, military ships and large outdoor commercial activities,

I believe The application of large-format metal laser cutting machines will become more and more extensive!