Advantages and process of four-roller sheet metal rolling machine

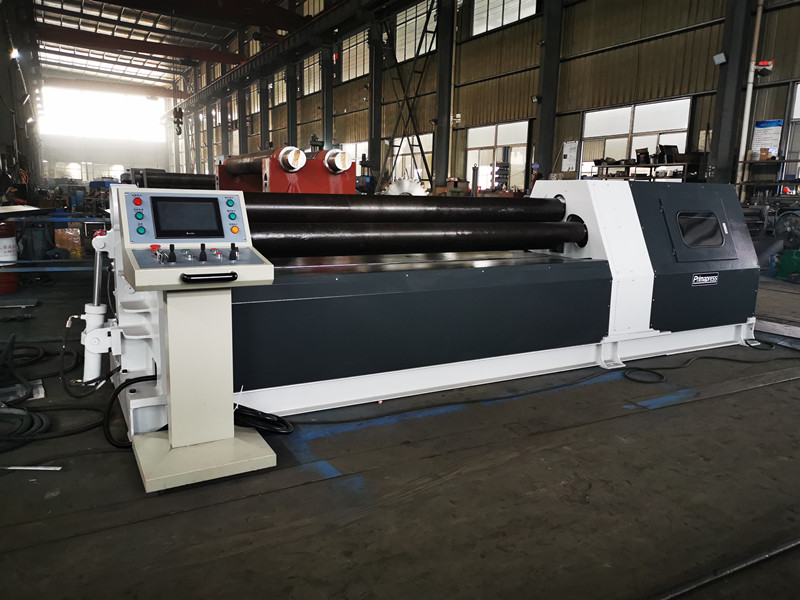

The English name of the four-roller sheet metal bending machine produced by the company is called (Four Roller Bending Machine or Four Roller plate Bending Machine) and has the following performance characteristics:

- It is very suitable for medium and thick plates or stainless steel plates;

- It is easy to roll the entire cylinder or parts of cylinders with different radii;

- The hydraulic inverted head frame facilitates the unloading of the rolled cylinder;

- Du Li mobile console is easy to operate;

- Weld the steel frame and eliminate the stress as a whole;

- The pinch rollers and side rollers are driven by hydraulic pistons to move;

- Overload safety protection;

- Three-channel digital output visually displays the position of the work roll.

The upper roller of the four-roll CNC metal plate bending machine is the driving roller, the lower roller and the side roller are the driven rollers, the position of the upper roller is fixed, the lower and side rollers can move up and down, the upper roller is driven by a hydraulic motor, and the rotation of the lower and side rollers is Driven by the friction between the steel plate and the rollers. The lower roller and the side roller are driven by the oil cylinders at both ends to realize the lifting movement.

The turning and resetting of the front bearing body of the upper roll are carried out by the oil cylinder, and the bearing body and the oil cylinder of each roll are installed in the frame at the left and right ends. The left and right frame is the main body of the four-roller sheet metal rolling machine, which adopts a welding structure and is installed on the integral base. The pushing device is to roll the workpiece, turn it over to the cylinder, and then push the workpiece out of the machine. All operations of the machine are carried out on the operating table.