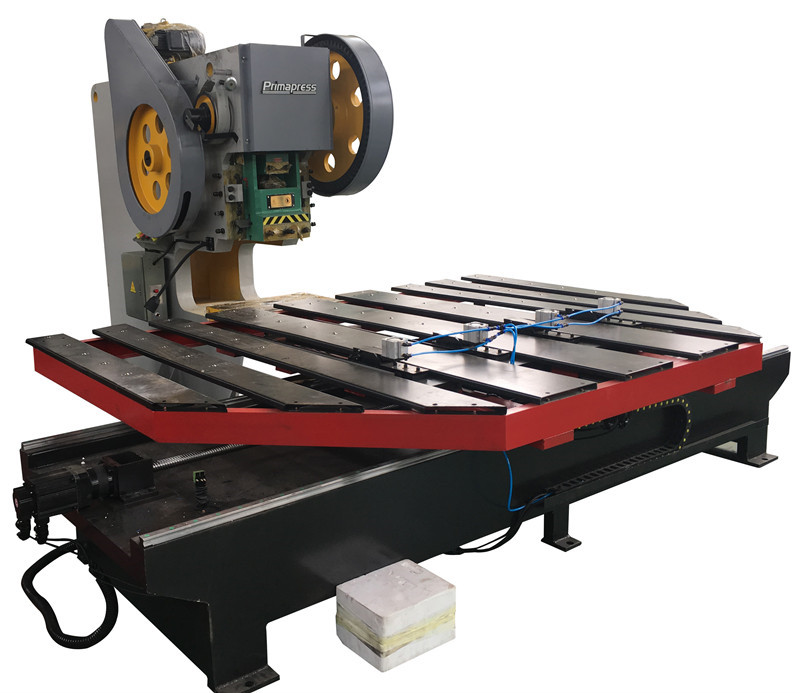

Description

Deep throat press machine with cnc feeding table

J21S mechanical Deep-throat press machine

| J21S-10 | J21S-16 | J21S-25A | J21S-40A | J21S-63A | J21S-80A | J21S-100A | J21S-125A | ||

| Capacity | kN | 100 | 160 | 250 | 400 | 630 | 800 | 1000 | 1250 |

| Nominal Force | mm | 2 | 2 | 2.5 | 4 | 4 | 5 | 6 | 6 |

| Slide Stroke | mm | 45 | 70 | 80 | 120 | 120 | 130 | 140 | 140 |

| SPM | min-1 | 145 | 125 | 60 | 55 | 50 | 45 | 38 | 38 |

| Max. Die Height | mm | 120 | 170 | 180 | 220 | 270 | 290 | 320 | 320 |

| Die Height Adjustment | mm | 30 | 45 | 70 | 80 | 80 | 100 | 100 | 100 |

| Between Slide Center & Frame | mm | 700 | 700 | 700 | 700 | 450/800 | 450/800 | 450/760 | 450/760 |

| Bolster (FB×LR) | mm | 200×310 | 320×480 | 400×600 | 480×700 | 480×710 | 580×860 | 710×1100 | 720×1200 |

| Bolster Opening (Up Hole Dia.×Dpth×Low Hole Dia.) | mm | Φ60 | Φ100 | Φ120 | Φ220×25×Φ180 | Φ200×45×Φ180 | Φ200×45×Φ180 | Φ260×50×Φ220 | Φ260×50×Φ220 |

| Bolster Thickness | mm | 40 | 60 | 70 | 80 | 90 | 100 | 120 | 120 |

| Bolster Opening (Dia.×FB×LR) | mm | Φ140×110×160 | Φ210×160×240 | 200×200 | 200×240 | 200×250 | 220×260 | 260×290 | 260×290 |

| Slide Area (FB×LR) | mm | 120×140 | 180×200 | 210×250 | 270×320 | 280×320 | 280×380 | 420×560 | 420×560 |

| Shank Hole (Dia.×Dpth) | mm | Φ30×55 | Φ40×60 | Φ40×70 | Φ50×70 | Φ50×80 | Φ60×75 | Φ60×80 | Φ60×80 |

| Between Columns | mm | 170 | 220 | 350 | 390 | 450 | 450 | 580 | 580 |

| Motor Power | kW | 0.75 | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 7.5 | 11 |

| Outline Size (FB×LR×H) | mm | 15800×7100×1525 | 1680×840×1880 | 1790×990×2288 | 1965×1180×2295 | 2220×1350×2600 | 2220×1380×2650 | 2530×1555×2990 | 2550×1610×2990 |

Automatic Feeder Table For Punching machine , Scope, Specification and Standard feature

1) Effective stroke 1000×1000mm(X×Y), This is Max. sheet size for punching in first locating too. It’s capable to punching 1000 wide sheet by means of turning around the sheet in second locating and the system assures position accuracy automatically. It have also automatic positioning of sheets. So the sheets can alwasy be put in the right position.

2) Accuracy ±0.1mm for distance between holes,Center linearity of holes ±0.1mm.

3) Feed Speed 25 m/min,

4) overall Dimension 1200×1000×620 mm.

5) Casting Frame, Tempered.

6) linear guide way and precision ball screw.

7) Table surface with balls or nylon brushes.

8) Pneumatic/manual Clamps(optional).

9) Dorna actuating motor.

10) One Set Electrical Control and Control cabinet

11) Control System ADTECH. The system is original created, which will be upgraded periodically, and allow automatic conversion and punching from AutoCAD.

12) Automatic reposition function, better for large volume production.

13) Control Cabinet (Main Operation Desk), with industrial PC and display

14) Power Supply: 3 KVA 380V/3 ph, 50Hz.(In accordance with power supply on site )

15) PLC is Xinjie Brand and servo motor is Beijing Huada

16) Precion ball screw and linear rail from Taiwan

17) Pneumatic clamping device