Flexible bending centers panel box folding machine advantages

Primapress 20 years of focus on sheet metal bending automation solutions!

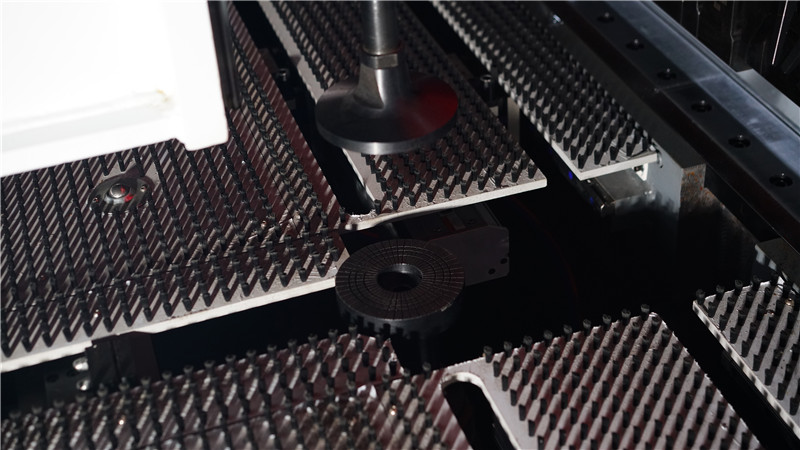

The flexible bending center, also known as the fully automatic multilateral bending center, can bend various complex shapes and easily achieve complex sheet metal bending requirements such as arcs, dead edges, returns, and closed shapes. Applied in the field of metal forming for different industries and workpieces.

Flexible bending center

What are the advantages of flexible bending centers panel box folding machine compared to traditional bending machines?

In terms of speed: The fastest fully automated bending process in the intelligent flexible bending center can reach 0.2 seconds per tool, greatly reducing the cycle time of multi sided and multi pass bending, which is more than three times the speed of traditional CNC bending machines. The more edges and more complex the workpiece, the greater the speed advantage.

In terms of safety: The intelligent flexible bending center does not require manual holding of workpieces, and the bending process is fully automated, greatly reducing the safety hazards caused by workers’ misoperation.

In terms of automation, the intelligent flexible bending center has reserved rich interfaces, making it convenient to connect with upstream and downstream production lines. It can be docked with a robotic arm to achieve automatic integrated loading and unloading.

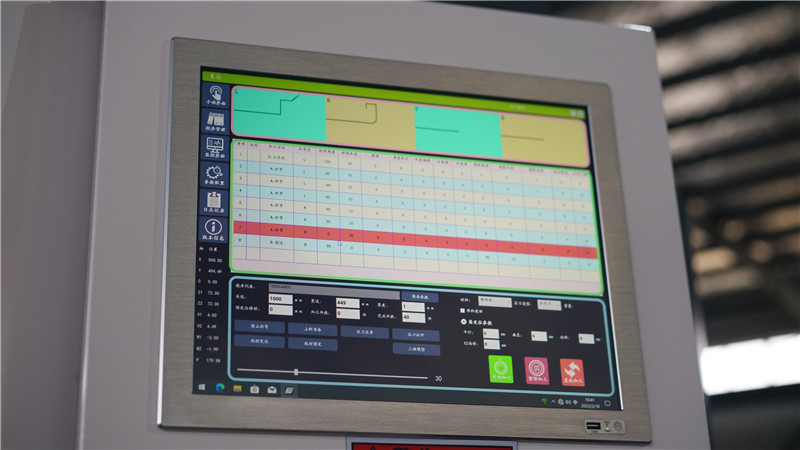

In terms of molds: The intelligent flexible bending center adopts a universal bending mold, which achieves bending of various shapes through multi axis concurrent linkage and full servo control. The traditional CNC bending machine needs a the first mock examination for each bend. It is more expensive to customize a special mold for each shape.

Flexible bending centers panel box folding machine have significant advantages over traditional bending machines in terms of bending accuracy, requirements, speed, safety, automation, and molds.