Characteristics and advantages of metal plate belt sander polishing deburring machines

Deburring machine is a grinding manufacturing tool used to remove burrs and sharp edges from the surface of metal products. It is a highly efficient tool that can be used in various industries and applications. In this article, we will explore the use of hand stabbing machines

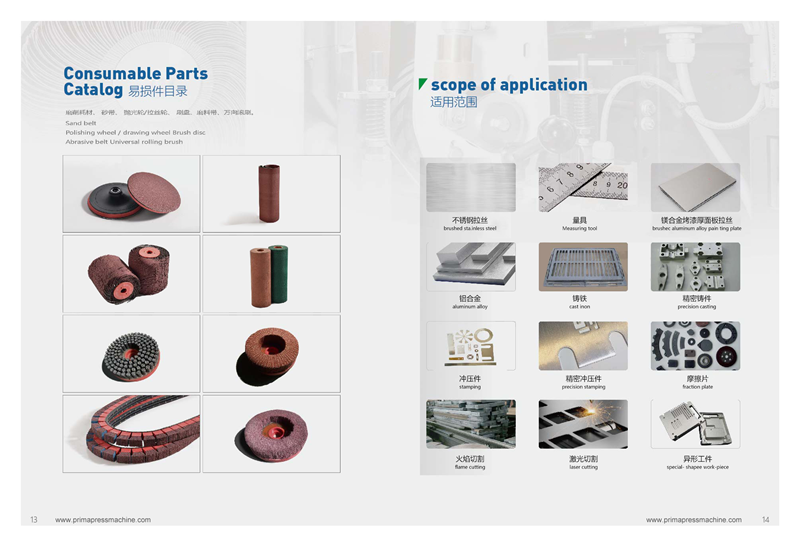

metal plate belt sander polishing deburring machines Advantages:

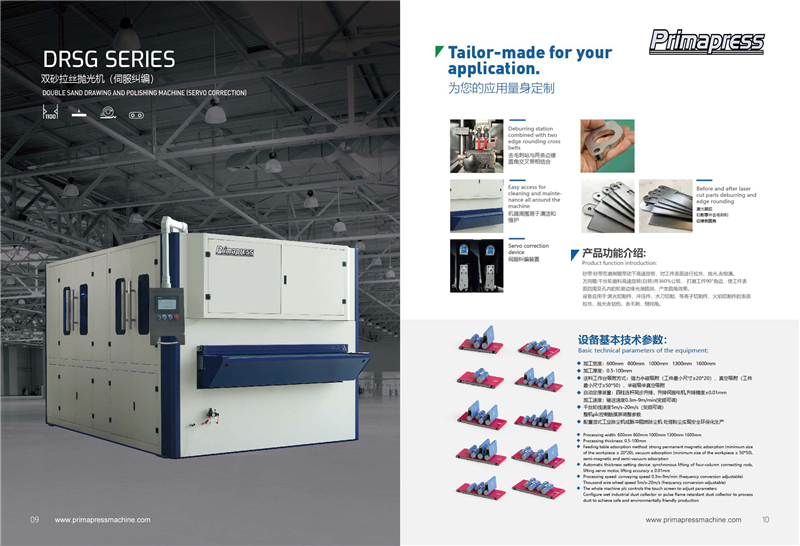

- Improve product quality: The deburring machine can effectively remove burrs and sharp edges on the surface of the product, thereby improving the quality and appearance of the product.

- Improve production efficiency: The deburring machine can quickly complete the cleaning task, thereby improving production efficiency and reducing production costs.

- Diversified manufacturing: metal plate belt sander polishing deburring machines can adapt to different materials and shapes, thus manufacturing diverse products.

- Safety and reliability: The deburring machine is safe, reliable, easy to operate, and easy to maintain.

metal plate belt sander polishing deburring machines Application field:

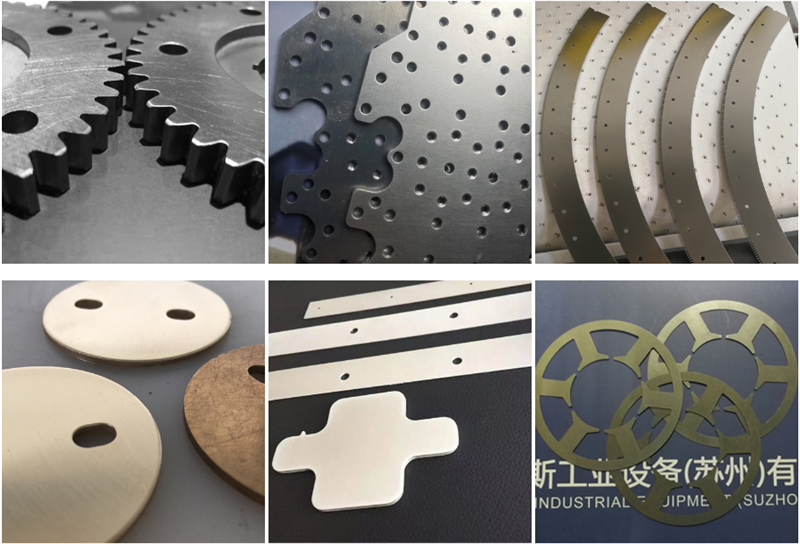

- Metal manufacturing: metal plate belt sander polishing deburring machines are widely used in the metal product processing industry, such as automobiles, kitchen utensils, furniture, etc

- Electronic industry: deburring machine can be used to remove burrs and sharp edges on PCB boards, thus improving product quality and connection reliability of electronic parts. 3. Medical industry: deburring machine can be used to manufacture medical devices, such as Scalpel, needle, etc

- Plastic industry: metal plate belt sander polishing deburring machines can be used to remove burrs and sharp edges from plastic products, thereby improving product quality and appearance. How to choose the correct deburring machine:

- Material: Select the deburring machine that is suitable for your material type. For example, for hard metal products, it is necessary to choose high-strength blades and precision machining. 2. Shape: Select a deburring machine that is suitable for the shape you need to process. For example, for irregularly shaped products, polishing heads and adaptive grinding materials need to be selected. 3. Processing requirements: Select a deburring machine that is suitable for your processing needs. For example, for products that must be processed with good performance, it is necessary to choose high-speed and high-precision machines. In short, the application of metal plate belt sander polishing deburring machines is extremely extensive, and different industries and applications need to choose different types of deburring and smoothing machines. It is necessary to choose equipment that is suitable for your processing needs and material types. When selecting a machine, it is necessary to pay attention to the safety characteristics and maintenance requirements of the machine. Proper operation and daily maintenance can extend the lifespan and efficiency of the machine.

The deburring machine is a centrifugal machine tool, which has a wide range of use and full functions. It is widely used in bicycle, auto parts, die-casting, zinc die-casting, furniture hardware, clothing hardware, luggage hardware, glasses accessories, watch accessories, locks, electronic accessories, computer accessories, Mobile phone accessories, various jewelry, jewelry and powder metallurgy industries.

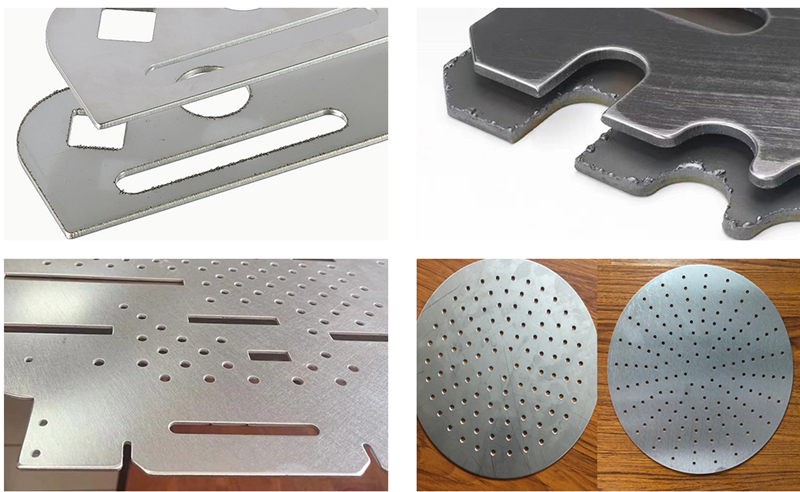

For seasonal items of different sizes, shapes, and materials, flash, fly, and wind up. Except for curtains, the sharp edges are small and round, with rust on the surface. After heat treatment, they undergo oxidation and peak quenching, black film, and surface polishing to eliminate residual processing pressure

Fully automatic deburring does not completely solve various complex shapes, extremely small and thin, variable, clamped, Cao like, dead corners, high-precision precision parts deburring, corner, oxide skin removal, rust removal, machining marks removal, roughness reduction, super deburring, high-precision deburring and smoothing. Fine hair removal, polishing, ultra precision, polishing, mirror matte, and other matte technology solutions.