Description

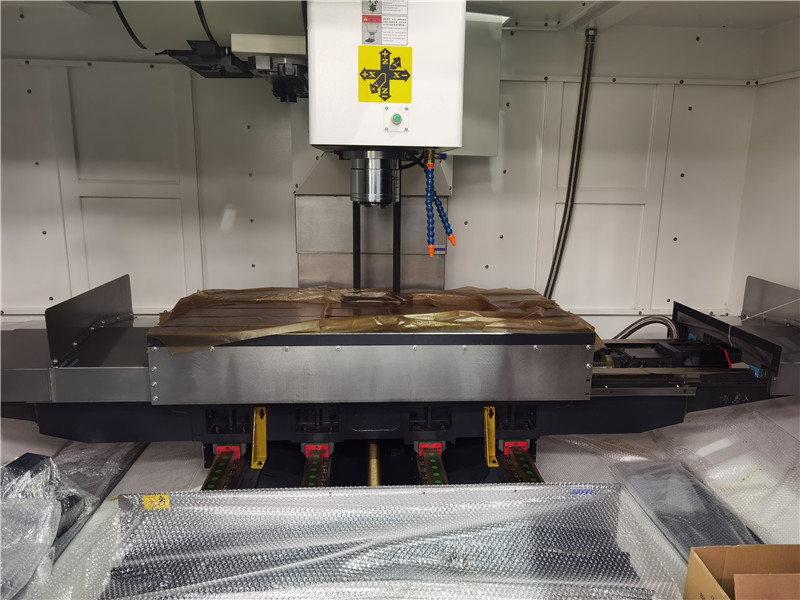

Horizontal Cnc Milling Machine cnc Horizontal Machining Center Horizontal Cnc Milling Machine Manufacturer

Horizontal Cnc Milling Machine Features: 1 Fixed column structure 2 Numerical control sub table, minimum 10, hydraulic clamping, suitable for heavy cutting. 3 Gas liquid conversion lift balance device 4 Z axia to the four rectangular hard rail;X axia to overload roller type linear guide rail;Y axia to rectangular hard rail Horizontal Machining Center Application: Horizontal machining center spindle speed is high, the rigidity is strong, the torque is big. The main shaft is equipped with cooling system, the automatic rotation of the double working table, reducing the auxiliary time, improve efficiency. This series of machine tool performance is perfect, the precision is stable, it is suitable for processing various types of box parts and two dimensional, three-dimensional surface, it is mechanical, automobile, communication, textile machinery, printing machinery, agricultural machinery and other industries processing box type parts of key equipment.

excellent precision performance. At the same time, it also has the ability to resist torsion and bending deformation, so as to support the entire Z-axis stroke to achieve the best straightness.

Model | Unit | HMC 50B |

Travel | ||

X-axis | mm | 750 |

Y-axis | mm | 750 |

Z-axis | mm | 750 |

Spindle | ||

Spindle center to worktable surface | mm | 50~800 |

Spindle nose to worktable center | mm | 135~885 |

Spindle taper | BT50 | |

Spindle speed | rpm/min | 10~6000 |

Spindle drive mode | Direct | |

Spindle motor | kw | Fanuc 11/18.5 |

Max.torque of spindle | Nm | 263/442 |

Worktable | ||

Table size | mm | 500*500 |

Division angle | deg | 0.001 |

Reference aperture | mm | Φ55H7 |

Max. load on worktable | kg | 600 |

Number of worktable | pcs | 1 |

Precision | ||

Positioning accuracy of rotary table | arc-sec | 10″ |

Repeated Positioning accuracy of rotary table | arc-sec | 6″ |

Positioning accuracy | mm | 0.012 |

Repeated Positioning accuracy | mm | 0.008 |

Feed speed | ||

Cutting speed X/Y/Z/W | m/min | 1-10 |

Rapid traverse speed X/Y/Z/W | m/min | 30/30/30 |

Tool magazine | ||

Capacity of tool magazine | 24 | |

Tool selection method | Random | |

Tool exchange mode | Arm type | |

Max. tool weight | kg | 15 |

Max. tool length | mm | 350 |

Tool change time | sec | 2 |

Max. tool diameter (no adjacent tool) | mm | Φ105/200 |

Others | ||

Air pressure | kgf/cm² | 6 |

Voltage | kva | 45 |

Tank Capacity | L | 700 |

Floor area (length*width*height) | mm | 5675*3625*3055 |

Weight | kg | 14000 |

Main accessories of Horizontal Cnc Milling Machine cnc Horizontal Machining Center Horizontal Cnc Milling Machine Manufacturer:

| S/N | Name | Quantity | Manufacturer | Specification Model

|

| 1 | system | 1 set

| Japan Fanuc | Fanuc 0i MF; 10.4 color LCD display

|

| 2 | Spindle servo motor | 1 set

| Japan Fanuc | β iI P30/8000

|

| 3 | X, Y, Z, B servo motors | 1 each | Japan Fanuc | β iS 30/2000 / β iS 40/2000 B/ β iS30/2000/ β iS 12/3000

|

| 4 | X, Y and Z axis lead screw bearings | One set of each | Germany FAG/Japan NSK | 35×72/35×72/40×72

|

| 5 | X, Y and Z axis ball screws | One set of each | Japanese THK/Taiwan HIWIN/PMI | GQ40/40/50 × 12-C3

|

| 6 | X axis linear guideway | 2 | Japanese THK/Taiwan HIWIN/PMI | 45 |

| 7 | Y-axis linear guide rail | 2 | Japanese THK/Taiwan HIWIN/PMI | 45 |

| 8 | Z-axis linear guideways | 2 | Japanese THK/Taiwan HIWIN/PMI | 55 |

| 9 | Tool magazine | 1 set | Okada | 24 disc type |

| 10 | Main shaft | 1 set of | tumblers/keys

| BT50-190

|

| 11 | Automatic lubrication system | 1 set of | Proton

| 4L

|

| 12 | Main pneumatic components | 1 set of | gold ware

| |

| 13 | Main electric components | 1 set | Schneider

| |

| 14 | Main drive toothed belt | 1 set | Japan UNITTA | |

| 15 | X, Y and Z shaft couplings | One set of each

| German KTR

| |

| 16 | A/C | 1 set | unit wide |

If any supplier fails to supply, it will be replaced by a brand of no less than the same quality.

Horizontal Cnc Milling Machine cnc Horizontal Machining Center Horizontal Cnc Milling Machine Manufacturer