Description

Metal Sanding machine Multi functional chamfer grinding polishing machine with filter and Vacuum table, dust collector

Automatic deburring machine model – PM1000

-PLC control system model-

-Processing width 1000mm

-Processing function: deburring, chamfering, wire drawing, polishing

-Vacuum adsorption

1、 Equipment function introduction

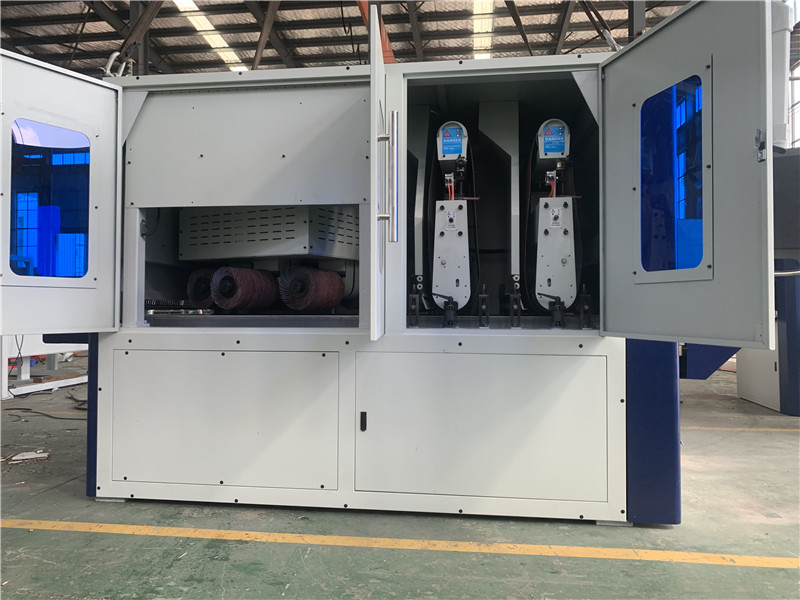

The PM1000 is an integrated equipment with a group of abrasive belts plus chamfering and deburring functions. This equipment is applicable to carbon steel plate, stainless steel plate, copper plate, etc. Adjust the corresponding grinding parameters and select the appropriate abrasive according to the different surface requirements of the workpiece.

Surface wire drawing and slag removal function

This equipment is equipped with two groups of wide abrasive belt structure. The abrasive belt rotates at high speed driven by the grinding roller to draw, polish and deburr the workpiece surface.

Fillet function

This equipment is equipped with a group of universal roller brush structures. The roller brush abrasive rotates at a high speed and rubs the edge of the workpiece surface to make the contour edges around the workpiece surface and inside the hole smooth and round, resulting in a round corner effect

Dust collection function (optional)

This equipment is equipped with a wet dust remover (5.5KW). Dust removal method: the dust generated by the host during operation is effectively absorbed by the dust remover.

Automatic deviation correction function of abrasive belt

This equipment is equipped with a set of pneumatic deviation correction system. Without manual intervention, the sandbelt can find the swing action point in a very short time, so that the sandbelt will not deviate, so that the parts will not deviate during processing.

High temperature wear-resistant and damping resistant conveyor belt

The equipment is equipped with high damping wear-resistant conveyor belt, and the conveyor structure and belt design are convenient for maintenance and replacement; The conveyor belt passes through high temperature during use, effectively adsorbing workpieces and increasing the service life of the conveyor belt.

Principle of abrasive belt mechanism

The deburring mechanism of this equipment is a wide abrasive belt structure. The abrasive belt mechanism is longitudinally arranged in a wide range. The lifting and tilting mechanisms are used, which can easily conduct high-precision wire drawing, blanking, curling and other hard burrs on the workpiece surface.

Principle of roller brush mechanism

The grinding mechanism of this equipment is a roller brush mechanism. The two rows of roller brushes of the roller brush mechanism are placed in parallel. Driven by the male axis, each roller brush rotates at a high speed to beat the workpiece, effectively remove the sharp edges of the workpiece surface contour, and form a smooth and beautiful chamfer effect.

Principle of fixing and conveying mechanism

The equipment is driven by high damping conveyor belt, and the conveying speed is adjustable by frequency conversion. The press roll clamping, electromagnetic suction cup adsorption and high pressure vacuum adsorption functions are used to fix and transport workpieces, which are suitable for polishing workpieces of various shapes.

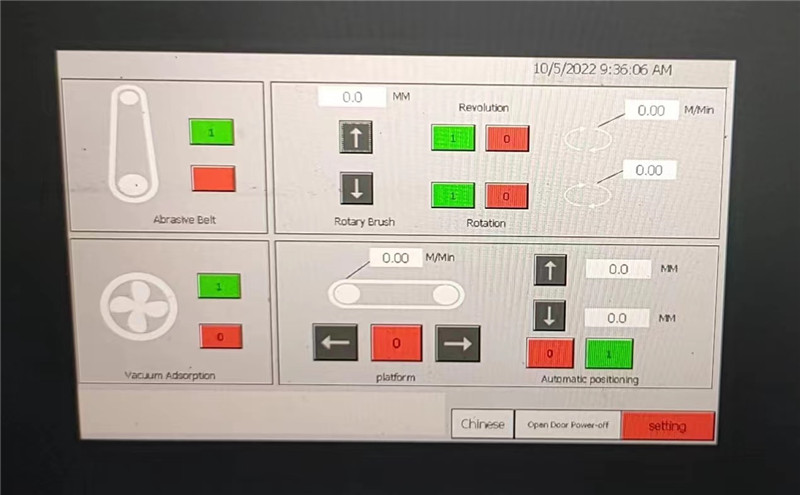

Operating system

This equipment is equipped with a Siemens high-definition touch screen, the whole machine is centrally controlled by Siemens PLC program, and has perfect self inspection function, safety protection function, alarm function, etc. The human-computer interface is simple and complete, the parameters input is easy to understand, the detailed and specific operation data is displayed in real time, and the self inspection feedback is timely and safe, so that the equipment is safe and easy to master.

2、 Technical indexes of equipment

Deburring machine PM1000 P1300

SN Description UOM Data

Wearing parts

S/N Type, specification, unit consumption, brand

1 Customization of belt grinding driving roller 1 Customization

2 V belt (abrasive belt part) 80 # 120 # 3 2200 * 1050

3 V belt (roller brush part) 80 # 6 300 * 300

4 High damping of conveyor belt, customized 1 6100 * 1050

Consumable life

Adjust the corresponding grinding parameters and select different abrasives according to the thickness, material and surface requirements of the workpiece; The following abrasive life is normal grinding life, and the abrasive life is different according to the shape and requirements of parts.

Abrasive belt (imported) ≥ 10 hours

Abrasive belt (domestic) ≥ 6 hours

Rolling brush (imported) 800 hours ≥ rolling brush ≥ 500 hours

Rolling brush (domestic) 500 hours ≥ rolling brush ≥ 300

Hours