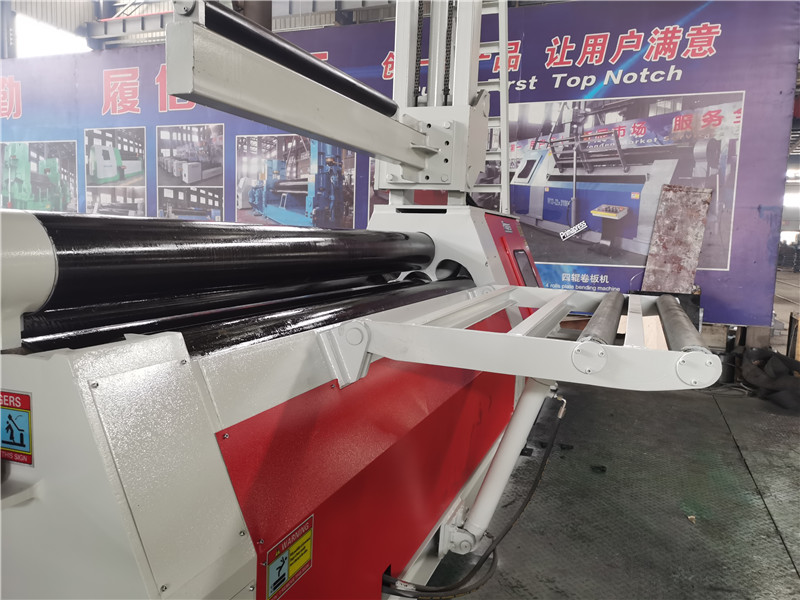

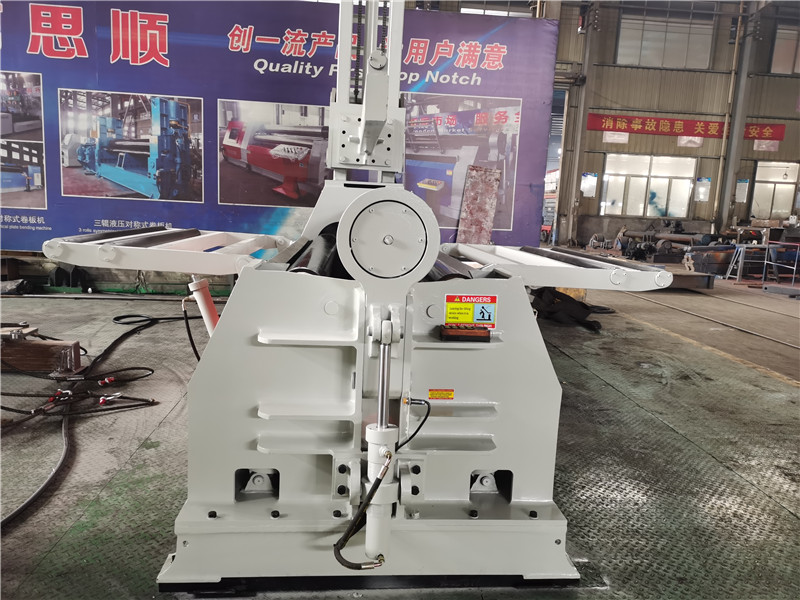

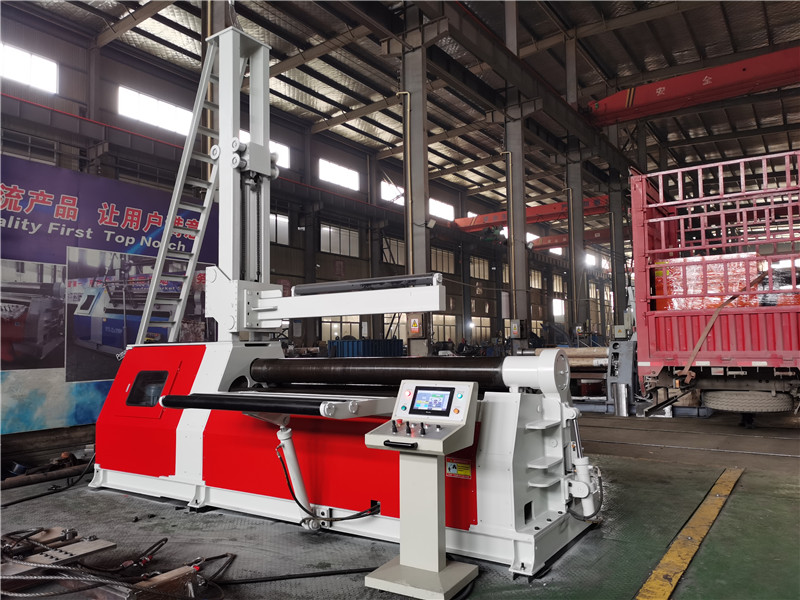

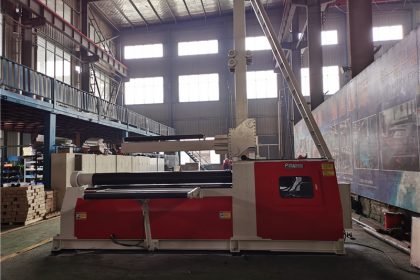

Main information of hydraulic cnc four roll plate bending rolling machine

hydraulic cnc four roll plate bending rolling machine is an instrument and equipment used for bending and forming of sheet metal

The hydraulic cnc four roll plate bending rolling machine is applicable to the bending and forming of metal plates. It can roll round, arc and conical workpieces within a certain range. It also has the pre bending function at the end of the plate. The remaining straight edges are small, and the work efficiency is high. It can also roughly level the metal plates on the machine.

Performance of plate rolling machine

Plate bending machine is a kind of public forging machine and equipment that can bend non-metallic plates into cones, spheres, cylinders or other shapes. This performance has been widely used in industries such as building, boiler steam, chemical industry, non-metallic structures and machine building. There is no shortage of new machines in the cause of change machines. It is because they are widely used by all walks of life that the cause of plate bending machine has developed at a high speed yesterday.

working principle

The upper roll position is fixed, and the lower roll moves upward in a straight line to clamp the steel plate. The curvature radius of the drum is adjusted by the linear or arc upward movement of the rollers on both sides. The four roller and three roller plate bending machines have different roller motion forms, but their working principles are the same. They both use the principle of three-point circle fixing to roll with different radii. However, the roundness of the pre bending straight edge and the rounding of the four roll bending machine is better than that of the three roll bending machine.

Safe Operation Procedures

- The bending machine must be managed by a specially assigned person.

- The operator must be familiar with the structural performance and use method of the plate bending machine, and can only operate after being approved by the responsible manager.

- Before starting the machine, carefully check whether the safety device is in good condition.

- During operation, it is strictly forbidden to put hands and feet on rollers, transmission parts and workpieces.

- After the work is interrupted, the clutch shall be set to neutral.

- Multi person cooperation must be commanded by a specially assigned person.

- Overload is strictly prohibited.

- The tilting and resetting of the upper roll lifting and turning bearing and the balancing of the upper roll must be carried out after the main drive stops.

- It is forbidden to pile up workpieces and sundries in the work site, and the machine tool and the site shall be kept clean at all times.

- After operation, cut off the power supply and lock the power box.