Bending characteristics and operation procedures of CNC plate press brake bending machine

According to the structural characteristics and working conditions of CNC plate press brake bending machine, the following simplification principles are determined:

- Simplify the parts that obviously will not affect the overall stiffness and strength of the fuselage, such as screw holes, pin holes, round corners, etc., and ignore some parts on the outer side plate and inner side plate for convenient lifting and installation of other devices

Small hole of.

- The guide rail is regarded as a free interface, and there is no force transfer between the slider and the guide rail.

- The foundation bolt fixing of the base plate is regarded as infinite stiffness, and the foundation bolt and the ground are regarded as fixed constraints.

- Ignore the accessories that have little impact on the overall stress condition.

- The connection strength of welding shall be equal to the strength of forgings.

- Keep the detailed structure of dangerous parts.

Share the safety operation procedures of the plate press brake bending machine

Safety Operation Procedures for plate press brake bending machine

- Strictly abide by the safety operation regulations of machine tool workers, and wear labor protection articles according to the regulations.

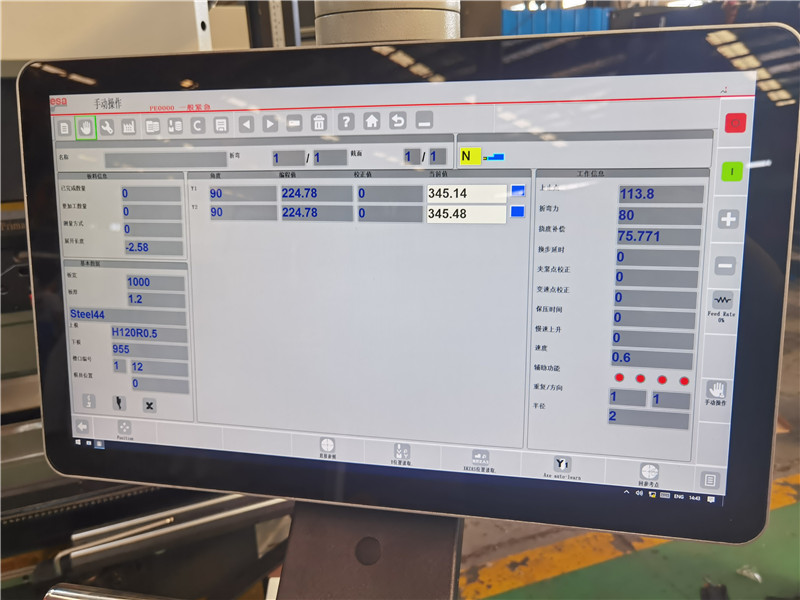

- Before starting, carefully check whether the motor, switch, circuit and grounding are normal and firm, and check whether all operating parts and buttons of the equipment are stuck in the correct position.

- Check the coincidence and firmness of upper and lower moulds; Check whether the positioning devices meet the requirements for processing.

- When the upper sliding plate and each positioning axis are not at the original point, run the return to the original point program.

- After the equipment is started, it will run without load for 1-2 minutes, and the upper sliding plate will move for 2-3 times at full stroke. If there is abnormal sound or fault, the vehicle shall be parked immediately, and the fault shall be eliminated. It can only work after everything is normal.

- One person shall command the work, so that the operator and the feeding and pressing staff can closely cooperate, and the bending signal can be sent only when the cooperating staff are in a safe position.

- The plate must be compacted during bending to prevent it from warping and hurting people.

- The power supply must be cut off when adjusting the plate material and pressing the mold, and the operation must be stopped before starting.

- When changing the opening of the variable lower die, no material is allowed to contact the lower die.

- No one is allowed to stand at the back of the machine tool when the machine tool is working.

- It is strictly forbidden to press the folded plate at one end.

- If the workpiece or die is found to be out of alignment during operation, it shall be parked for correction. It is strictly prohibited to correct the workpiece or die manually to prevent hand injury.

- It is forbidden to bend super thick iron plates or quenched steel plates, high-grade alloy steels, square steels and plates beyond the function of the plate plate press brake bending machineto avoid damaging the machine tool.

- Frequently check the coincidence of upper and lower moulds; Whether the indication of the pressure gauge conforms to the designation.

- stop the machine immediately in case of abnormality, check the cause and eliminate it in time.

- Before shutdown, place wood blocks on the lower formwork under the oil cylinders on both sides to lower the upper sliding plate onto the wood blocks.

- Exit the control system program first, and then cut off the power supply.