Briefly describe the common faults and solutions of tube-sheet integrated fiber laser cutting machine

Product features of dual-purpose fiber laser cutting machine for tube sheet

Better beam quality: smaller focusing spot, finer cutting line, smooth incision, beautiful appearance, no deformation, higher work efficiency, better processing quality; high stability: using fiber laser, compact structure, small size, Using a fixed optical path, the energy consumption is small, and the cutting quality is stable.

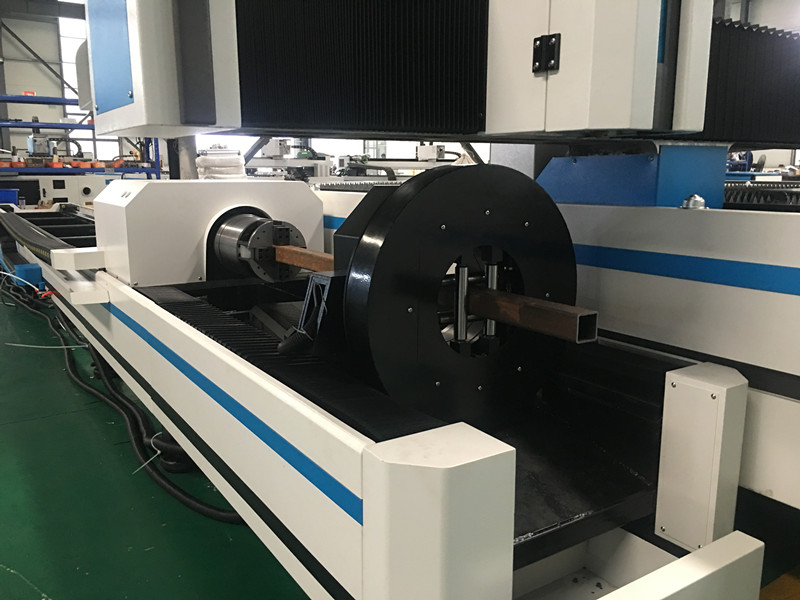

One machine is multi-purpose, which can not only meet the customer’s cutting requirements for flat plates, but also meet the cutting of round pipes and special-shaped pipes (square steel, flat iron, channel steel, square pipe), with high cost performance.

Chuck clamping system, the self-adjusting center of the chuck, automatically adjusts the clamping force according to the profile specifications to ensure that the thin tube is clamped without damage.

High temperature tempering at 600°C, cooling with furnace for 24 hours, imported gantry milling finishing, precision carbon dioxide protection welding, to ensure 20 years of normal use without deformation.

The tube-sheet integrated laser cutting machine is to focus the laser emitted from the laser into a high power density laser beam through the optical path system. The laser beam is irradiated on the surface of the workpiece, making the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the beam blows the molten or vaporized metal away.

Let’s take a look at the causes and solutions of common failures of the lower tube-sheet integrated laser cutting machine:

- When machining carbon steel, burrs on the workpiece generally cause burrs on the workpiece. The possible reasons include:

(1) If the laser focus position is shifted, do the focus position test and adjust it according to the offset of the laser focus;

(2) The output power of the laser is not enough. It is necessary to check whether the laser generator is working normally. If it is normal, observe whether the output value of the laser control button is correct. If it is not correct, adjust it;

(3) The cutting line speed is too slow, and it is necessary to increase the line speed during operation control;

(4) The purity of the cutting gas is not enough, and it is necessary to provide high-quality cutting working gas;

(5) If the machine tool runs for too long, the instability occurs, at this time, it needs to be shut down and restarted.

- Reasons for incomplete laser cutting:

(1) The selection of the laser nozzle does not match the thickness of the processing plate, so replace the nozzle or processing plate;

(2) The line speed of laser pipe cutting processing is too fast, and operation control is required to reduce the line speed.

- Abnormal sparks appear when cutting low-carbon steel. When cutting low-carbon steel normally, the sparks are long and flat, with fewer split ends. When abnormal spark occurs, it will affect the smoothness and processing quality of the cutting section of the workpiece. At this time, when other parameters are normal, the following situations should be considered:

(1) The nozzle of the laser head is seriously worn, and the nozzle should be replaced in time;

(2) In the case of no new nozzle replacement, the cutting working gas pressure should be increased;

(3) If the thread at the connection between the nozzle and the laser head is loose, the cutting should be stopped immediately at this time, check the connection state of the laser head, and re-thread the thread.