Structure introduction and operation process of hydraulic sheet metal shearing machine

The sheet metal shearing machine cuts the sheet material by the overlapping movement of the upper and lower blades. The lower inserts all have four edges, that is, the inserts are rectangular in cross section. The blade of the sheet metal shearing machine in which the blade holder moves in a straight line forward can have two edges or four edges. The upper blade of the sheet metal shearing machine with the tool rest moving along the arc should only have two edges, that is, the blade section is diamond-shaped, and the upper blade must be adjusted to a space curved surface with screws or spacers. The shear length of the sheet is measured and controlled by the CNC back gauge. The blade clearance required for different plate thicknesses is different, so the clearance between the upper and lower blades can be adjusted by the fulcrum and the clearance adjustment device.

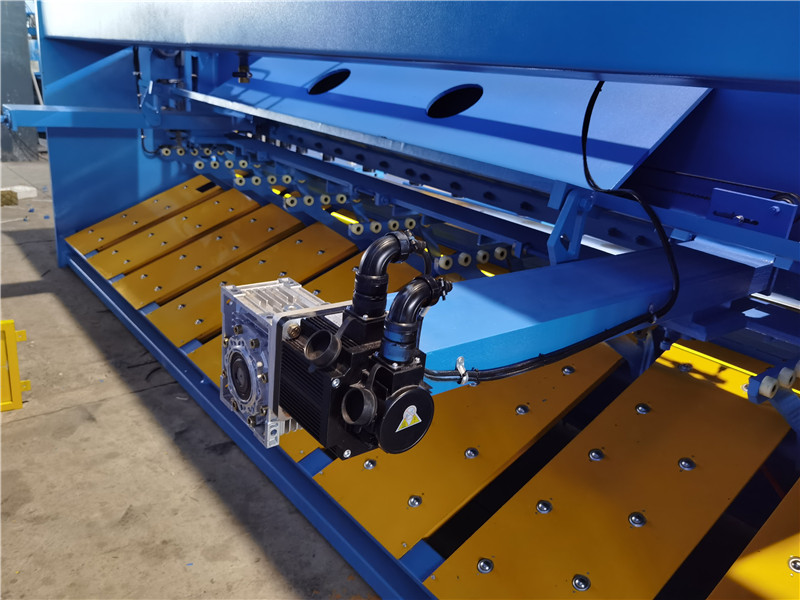

After the CNC sheet metal shearing machine is sheared, the straightness and parallelism of the shearing surface of the sheared plate should be guaranteed, and the distortion of the plate should be minimized to obtain high-quality workpieces. The upper blade is fixed on the knife holder, and the lower blade is fixed on the worktable. A material support ball is installed on the worktable, so that the sheet will not be scratched when sliding on it. The back gauge is used for sheet positioning, and the position is adjusted by the motor. The pressing cylinder is used to press the sheet to prevent the sheet from moving during shearing. Guardrails are safety devices to prevent workplace accidents. The return journey generally relies on nitrogen, which is fast and has a small impact.

Operating procedures of CNC sheet metal shearing machine:

- Before work, do it carefully before doing the dry running test. The manual cranking should be used for a working stroke first, and the equipment can be started only after confirming that it is normal. Equipment with hydraulic devices, check the oil volume of the oil storage tank should be sufficient. After starting the oil pump, check whether there is leakage in the valve and pipeline, and the pressure should meet the requirements. Open the bleed valve to let air out of the system.

- Seriously do not allow to cut laminated sheets during work. It is not allowed to cut narrow sheets and short sheets that are not tightly compressed. It is not allowed to trim the edge of the burr sheet. The gap between the blades should be adjusted according to the thickness of the sheet, but it should not be larger than 1/30 of the plate. Afterwards, manual turning inspection shall be applied to avoid accidents. The cutting edge of the blade should be kept sharp. If the cutting edge becomes flaky or cracked, it should be replaced in time. When cutting, the pressing device should firmly press the sheet, and it is not allowed to cut in a state where it is not pressed tightly. For equipment with hydraulic devices, other than throttling and cutting, other hydraulic valves are not allowed to be adjusted without permission.

The hydraulic sheet metal shearing machine is a machine that uses one blade to reciprocate linear motion relative to the other blade to cut the plate. With the help of the moving upper blade and the fixed lower blade, a reasonable blade gap is used to apply shearing force to the metal plates of various thicknesses, so that the plates are broken and separated according to the required size. sheet metal shearing machine is a kind of forging machinery, and its main function is the metal processing industry. The equipment includes a main body and a transfer table, the transfer table is fixedly installed on the end face of the main body of the sheet metal shearing machine, a lower blade is fixedly installed in the middle of the transfer table, an upper blade is arranged directly above the lower blade, and a hydraulic pusher is fixedly connected to the upper end of the upper blade. The outer side wall of the main body of the sheet metal shearing machine is fixedly installed with a fastening seat, and one end of the transmission table is fixedly installed with a feeding table, and the bottom of the feeding table is provided with a bearing frame, which improves the intelligence of the sheet metal shearing machine.

Instructions for safe operation of hydraulic shears:

- Machine tool operators are not allowed to operate without training permission.

- The operator must be familiar with the structure, performance and equipment troubleshooting of the machine tool. Special personnel are responsible, and illegal operations are strictly prohibited.

- Before starting the machine, check whether the mechanical parts are normal, whether the hydraulic system is normal, whether there is oil pollution or impurities inside and outside the equipment, and keep the equipment in good condition, the working environment is clean and the safety passage is unblocked before operation.

- After turning on the power, start the oil pump motor according to the electrical system instructions, and check whether the direction indicated by the oil pump oil sign is correct; Affect the normal operation of other electrical components.

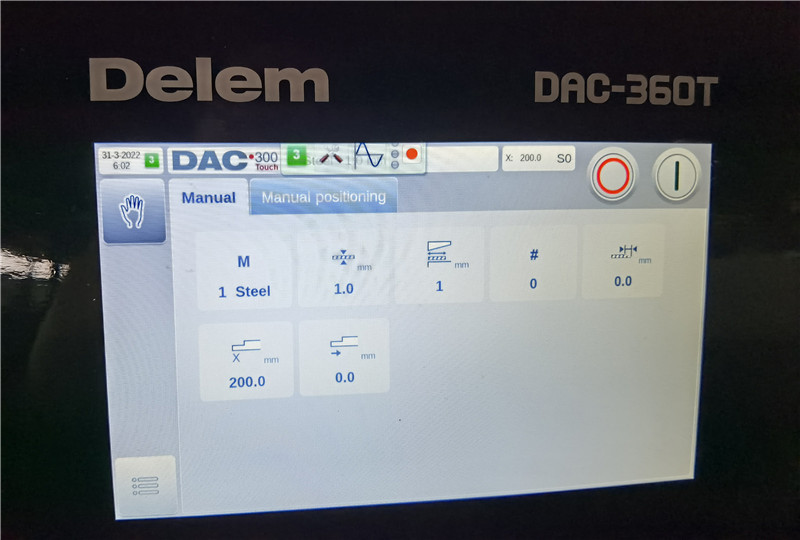

- Before cutting, adjust the clearance of the blade edge according to the cutting thickness as required, and run the manual empty car several times. Adjust the pressure of the hydraulic system, and stop the machine for trial shearing when no abnormal conditions are found.

- If abnormal noise or overheating of oil is found during operation, it should be stopped immediately for inspection.