The use of follow-up front support arm in CNC plate press brake bending machine

Sheet metal CNC plate press brake bending machine is a widely used bending equipment. With the development of science and technology, CNC plate press brake bending machine has entered the era of CNC. People have higher and higher requirements for bending accuracy, and the functional components of CNC plate press brake bending machines are becoming more and more diverse. Powerful companies pay more and more attention to the development of various characteristic functional components and strive to improve the automation degree of machine tools. The follow-up feeding mechanism is one of the more complex functional components. At present, most factories are manually supporting materials. For ordinary small materials, only one person can operate a CNC sheet metal bending machine. However, when large-area sheet metal is involved, it often takes 4 to 6 people to operate a CNC sheet metal bending machine. Bender. It is extremely labor-intensive, and the instability of artificial support can easily cause product quality problems and is not conducive to production control. From this point of view, a follow-up material bending trolley greatly improves production efficiency, so how to choose to maximize the benefits of the factory: 1. The factory already has a CNC sheet metal bending machine, then as long as it is equipped with Follow the front support trolley, and add a set (magnetic scale) to the existing CNC plate press brake bending machine to obtain the positioning signal, which is simple, convenient and easy to operate.

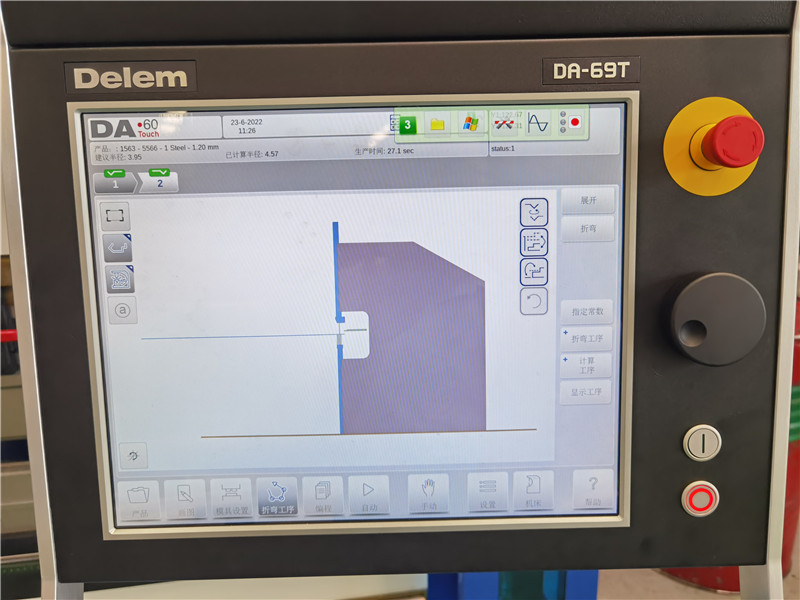

CNC plate press brake bending machine follow-up trolley

The bending follower is a semi-automatic tool that assists the bending workers to do the upturning action during the bending process. The servo bending follower is different from the follower device on the market. There is no requirement for the main shaft, and the follow-up car has an independent control system, which can be moved and used in conjunction with any bending equipment on the production site. During the first installation, the interface of the CNC plate press brake bending machine and the parameters of the follow-up car are debugged, and the next time The connection only needs to manually adjust the height of the car, and call up the follow-up parameters of the current CNC sheet metal bending machine, and then it can be used.,

CNC plate press brake bending machine follow-up trolley

- Newly purchased CNC plate press brake bending machine, CNC plate press brake bending machineequipped with follow-up mechanism, the CNC plate press brake bending machinefollow-up front support device is fixed on the CNC plate press brake bending machine, which is convenient and quick to operate and has high processing accuracy. Reduce work intensity and improve work efficiency. The front support device of the CNC plate press brake bending machine can be customized according to customer requirements, which is convenient for high-quality bending processing. The CNC plate press brake bending machine follows the front support device

The servo bending follow-up CNC plate press brake bending machine trolley and the bending forming machine can quickly form a semi-automation, which can quickly and flexibly proofing and mass production while saving labor, and has good economic benefits.