Description

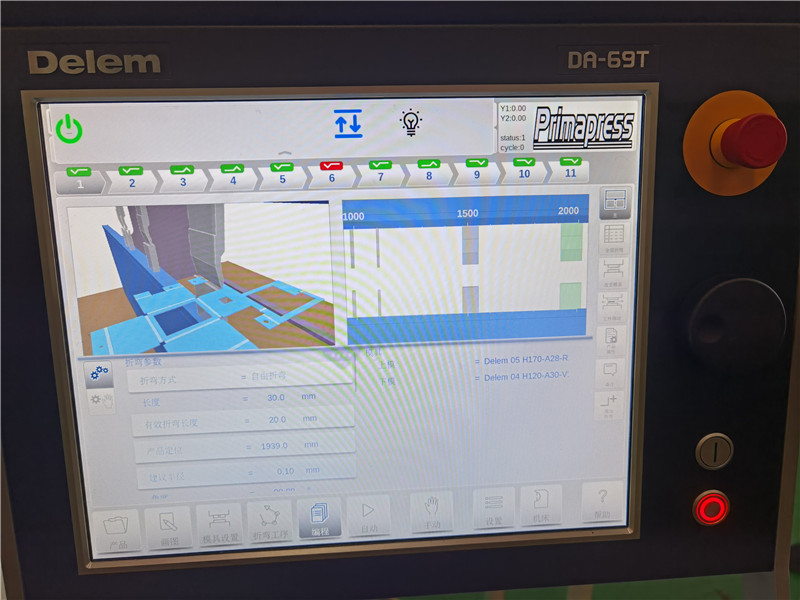

170T2500 DA69T Hybrid cnc synchronous sheet metal press brake bending machine 8+1 Axis

Required specifications for reference.

| No | Items | parameters | remarks | Leading Bending technology

Excellent Manufacturer

if you need more informations, contact Primapress sales team. |

| 1 | Nominal force | 1750KN | ||

| 2 | Bending length | 3200mm | ||

| 3 | Distance between | 2750mm | ||

| 4 | Throat | 410mm | ||

| 5 | Stroke | 200 mm | ||

| 6 | Max open height | 420 mm | ||

| 7 | X,Y axis travel | repeat positioning accuracy: ±0.01mm | ||

| 8 | Approach speed | 160 mm/s | Three Speed is adjustable in DA69T controller | |

| 9 | Working speed | 120mm/s | ||

| 10 | Backing speed | 160 mm/s | ||

| 11 | Control axis | 8+1 -AXIS for Y1 , Y2 , X1,X2, R1,R2,Z1,Z2 ,-axis and v crowning axis | ||

| 12 | Dimension | 3550x1700x2700mm | Removable | |

| 13 | Electrics | 220V/60Hz/3Ph | Optional | |

| 14 | Motor | 11 | Kw | |

Attachment with the machine& Machine key components list

| No. | 1 years spares | Remark | Name | Origin | |

| 1- | Grease gun& foot switch | Free of charge | Asynchronous motor | Siemens, Germany | |

| 2- | Keys to button lock and electric cabinet lock | FOC | Controller | Delem DA69T, Holland | |

| 3- | Foundation bolts | FOC | Transformer | SCHNEIDER | |

| 4- | O-type sealing rings | FOC | AC contactor | SCHNEIDER | |

| 5- | Combined washers | FOC | Circuit Breakers | SCHNEIDER | |

| 6- | Mobile type foot switch | Servo motor | Estun | ||

| 7- | Operation & maintenance manual | In English | Gear pump | Siemens pump | |

| 8- | Electrical diagram | In English | Sealing parts | Valqua ,Japan | |

| 9- | Operation Instruction ENGLISH Operation Instruction(Machine) Packing list, Instruction of System Certificates of quality | Hydraulic Integrated Systems | Bosch, Germany, | ||

| Quick release | China Shanghai | ||||

The Whole Structure of Press Brake:

Totally European design, streamlined looking

Taking off inner-stress of welded parts by tempering, good stability

Remove rust with sand-blast and coated with anti-rust paint

Adopt Spanish pentahedron machine center, once clamping can finish all working surfaces which will

guarantee dimension precision and position precision.

The design of the machine frame is a critical part of any machine with relation to its ability to produce accurate parts for a long period of time.

Frames, assembly surfaces and connection holes are machined after the welding process, up to 60′ in a single pass.

Supplying three front sheet supports , Finish of Nippon Polyurethane paint.

The Whole Structure of Press Brake:

Totally European design, streamlined looking

Taking off inner-stress of welded parts by tempering, good stability

Remove rust with sand-blast and coated with anti-rust paint

Frames, assembly surfaces and connection holes are machined after the welding process, up to 60′ in a single pass.

Supplying three front sheet supports , Finish of Nippon Polyurethane paint

2) Ram structure:

Upper stroke design for bending, low noise, stable operating situation , Parallel tolerance of Y1 and Y2 is 0.01mm

Y1,Y2 can be programmed separately can work under non-balance load, can bend cone-shape work piece

At bottom dead center a pressure-keeping time is offered, and can be programmed to assure precision of all kinds of work piece. Can move the ram up slowly, which allows the operator to control work piece conveniently Universal fixing-surface of the upper tool can be meeting with the clamping requirement of the tool farthest!