Plasma cutting machine and metal fiber metal sheet laser cutting machine which is better

The principle of sheet metal laser cutting machine

Sheet metal laser cutting is the use of a focused high-power density sheet metal laser beam to irradiate the workpiece to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam. Metal is melted and vaporized to form the desired shape, which is one of the thermal cutting methods.

The principle of plasma cutting machine

Plasma cutting is to heat the gas to an extremely high temperature to be ionized and then transfer the arc power to the cutting workpiece, and the workpiece is melted and blown away

by extremely high heat to form the working state of plasma arc cutting. Plasma cutting has shortcomings such as strong arc light, high noise, and easy generation of dust. However,

the plasma cutting speed is fast, and it has considerable advantages in the cutting of various non-ferrous metals.

Plasma cutting machine and metal fiber metal sheet laser cutting machine which is better

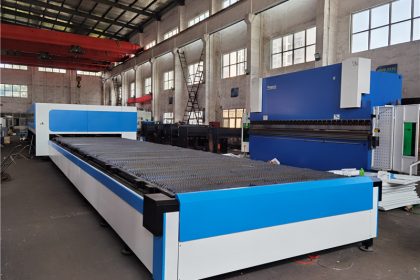

Simply put, sheet metal laser cutting is a more accurate and faster method of cutting complex and complex shapes of metal. Since sheet metal laser cutting is a non-contact processing method,

the metal sheet laser cutting process will not damage the metal, and the nozzle of the plasma cutting machine may cause damage to the metal. Since the entire sheet metal laser cutting process is based on a detailed CAD drawing, the process can be repeated quickly and easily.

Compared with other cutting methods, sheet metal laser cutting has many advantages:

Due to the precision of sheet metal laser cutting, parts with smooth cut surfaces can be produced-the surface can be directly used for welding and manufacturing without any other changes or grinding, saving time and money in the manufacturing process.

The metal fiber metal sheet laser cutting machine is a faster and more efficient cutting method. The metal fiber metal sheet laser cutting machine operates 7 days a week and runs 24 hours a day, producing parts faster than traditional manufacturing methods. This means that we can maintain the shortest industry lead time and turnaround time.

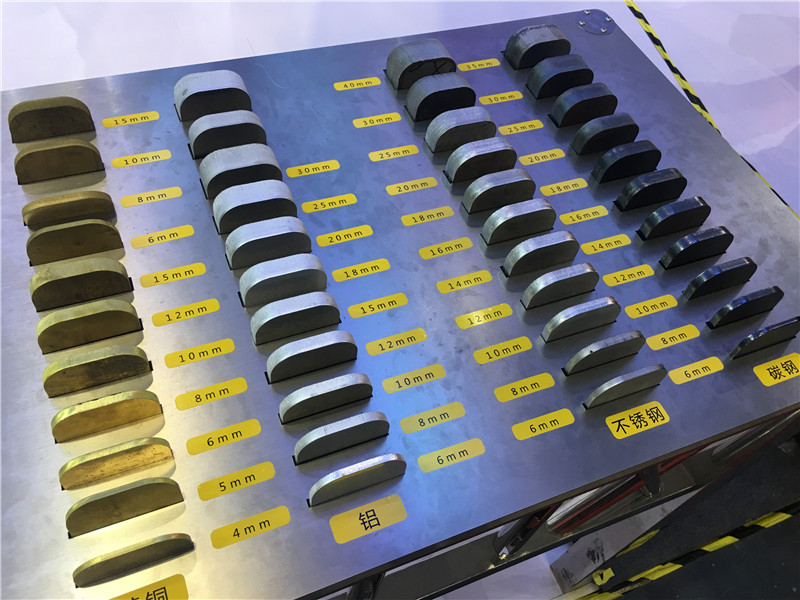

The sheet metal laser can cut a variety of metals such as stainless steel, aluminum, copper, brass and mild steel, and the downtime during the switching process is very short.

Sheet metal laser cutting is a more accurate method of cutting parts, with an error of ±0.2 mm.

The above comparison is not difficult to see that the metal fiber metal sheet laser cutting machine has higher efficiency than plasma cutting, and the processing precision is also unattainable by the plasma metal fiber metal sheet laser cutting machine. The metal fiber metal sheet laser cutting machine The initial cost of purchasing equipment may be relatively high, but in the long run, it can bring more benefits for manufacturers!

sheet metal Plasma cutting machine