Market application of 12kw 15kw 20kw 30kW ultra-high power metal fiber laser cutting equipment

Today’s sheet metal welding process is roughly as follows: sheet metal blanking → sheet edge processing → assembly and welding → heat treatment → machining → completion.

The blanking and cutting of the sheet metal is the first step in the welding process. It is currently the conventional one on the market. The plate cutting process is roughly divided into:

flame cutting, plasma cutting and metal fiber laser cutting.

Comparison of plate cutting methods

The main method for cutting medium and thick plates was oxyacetylene flame cutting in the 1950s and 1960s; after the 1970s, in order to improve and improve the cutting quality of flame cutting, oxyethane precision flame cutting and plasma cutting were promoted. Various cutting methods have their advantages and disadvantages, and have a certain scope of application in industrial production.

Flame cutting is a common method for rough machining of steel plates. The cost of cutting equipment is low, and it is the only economical and effective method for cutting thick metal plates. However, compared with plasma, the heat affected zone of flame cutting is much larger, and the thermal deformation is also relatively large. Cutting, and the environmental pollution is more serious.

Plasma cutting has a wide cutting area and can cut all metal plates. The cutting speed is fast, the efficiency is high, and the cutting accuracy is higher than that of flame cutting. However, the cutting of thick plates has a large taper and a wide slit. In the case of batch processing, a large amount of material waste will be caused, and a large amount of harmful gas and a large amount

of smoke will be generated, which will cause pollution.

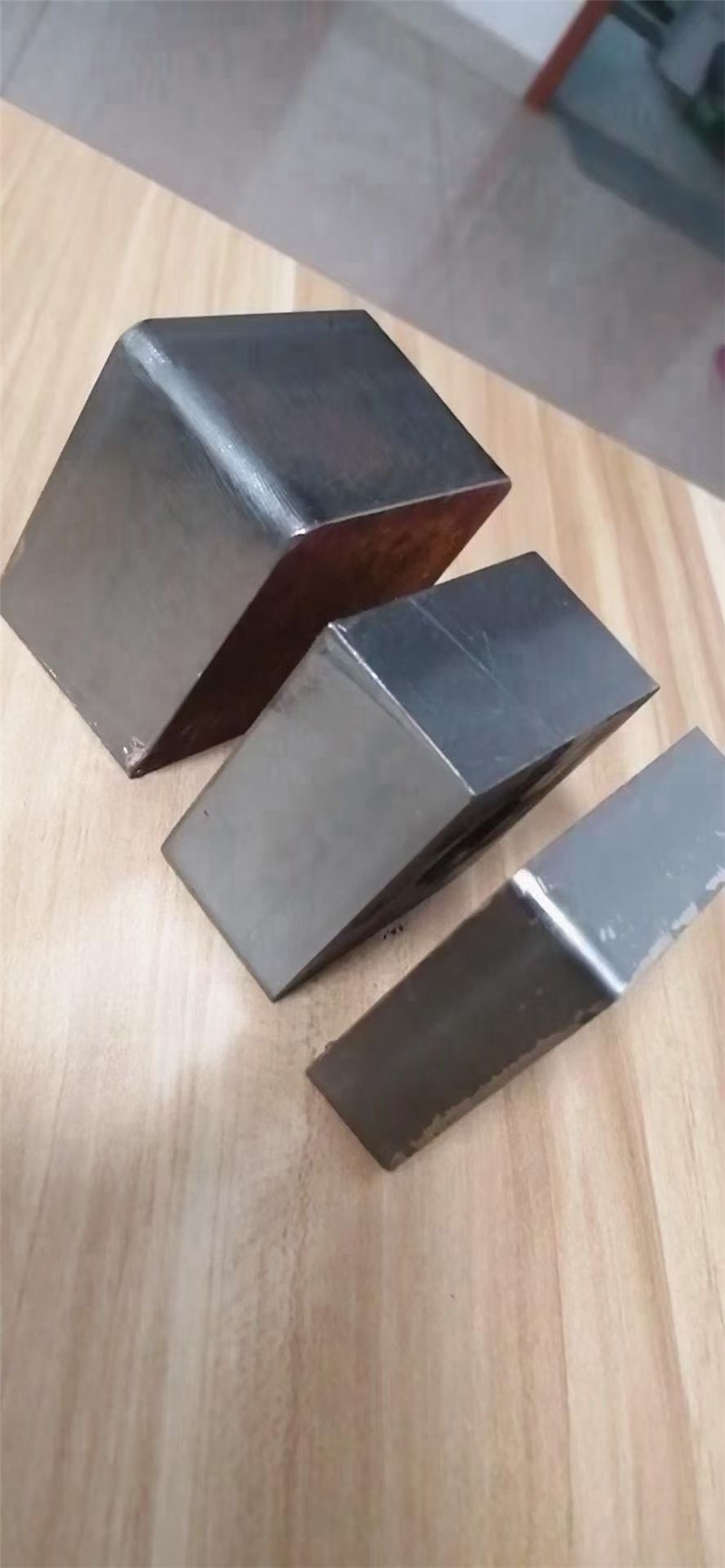

Compared with traditional cutting processes such as oxyacetylene and plasma, the metal fiber laser cutting speed is fast, the slit is narrow, the heat-affected zone is small, the edge of the slit

is perpendicular, the cutting edge is smooth, and there are many types of materials that can be cut. The emergence of metal fiber laser cutting technology has opened up a new field of industrial application of metal fiber laser technology. The application market prospects in microelectronics, rail transit, molds, automobile manufacturing and other fields are broad. The development

and application of metal fiber laser cutting machines are undoubtedly It is a major improvement and innovation breakthrough in modern industrial production.

High-power metal fiber laser cutting technology

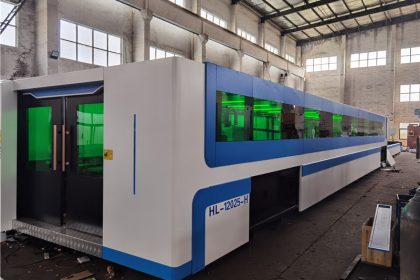

Market application of 12kw 15kw 20kw 30kW ultra-high power metal fiber laser cutting equipment

With the continuous development of today’s heavy industry, metal fiber laser cutting has gradually transitioned from the thin plate cutting industry to the thick plate cutting field,

With the continuous development of today’s heavy industry, metal fiber laser cutting has gradually transitioned from the thin plate cutting industry to the thick plate cutting field,

which means that metal fiber laser cutting will enter the era of high power.

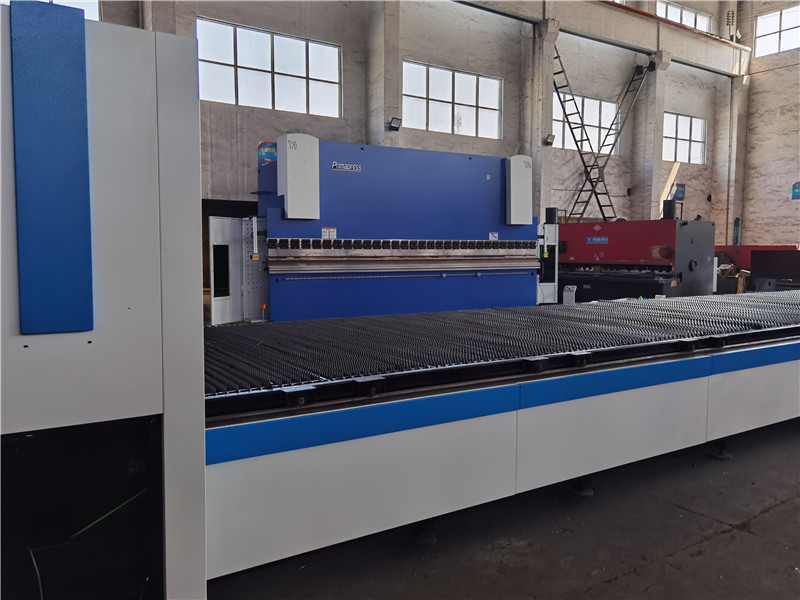

In response to the new requirements of metal cutting precision and thickness in the new era of industrial manufacturing, the achievable power of metal fiber laser cutting machines is

getting higher and higher. Nowadays, high-power metal fiber laser cutting equipment has been widely used in the upstream of almost all sheet processing products, ranging from space shuttles, ships, automobiles, to washing machines, refrigerators, air conditioners, etc., are inseparable from high-power metal fiber laser cutting machines. . In addition to industrial manufacturing,

high-power metal fiber laser technology and equipment are also one of the commanding heights of national defense strategy and emerging industries, and play a major support role in national security and national economic construction. From the perspective of industrial development, high power is an inevitable product of the development of the metal fiber laser cutting industry

to a certain stage, and it is also the general trend of the industry.

In the sheet metal processing industry, metal fiber laser cutting machines have established unique processing advantages, showing high efficiency, high quality, and high precision, and are gradually replacing traditional processing techniques. However, in the field of medium and heavy plate processing, metal fiber laser cutting is facing some difficulties: thick plate cutting

requires higher power of metal fiber laser equipment, which is technically difficult; high-power metal fiber laser cutting high-end technology is monopolized by advanced foreign companies,

and domestic Technological development is controlled by others; as the thickness of the plate increases, the cutting process becomes more and more difficult, requiring a lot of experimentation and exploration to obtain stable cutting process parameters; the thicker the plate, the slower the cutting speed, and the user’s production efficiency will be severely affected. Restrictions:

With the increase of power and plate thickness, the load-bearing capacity, anti-scorching ability, and dust removal ability of the cutting machine itself need to be improved accordingly.