The application of sheet metal laser welding machine and the advantages of hand-held sheet metal laser welding machine

Sheet metal laser welding uses high-energy sheet metal laser pulses to locally heat the material in a small area at a high speed. The energy radiated by the sheet metal laser diffuses

to the inside of the material through heat conduction, and the material is melted in a short time to form a specific molten pool . And quickly cool and condense to connect the

materials together. It is a new type of welding method. The laser welding of sheet metal is mainly aimed at the welding of thin-walled materials and precision parts.

It can realize spot welding, butt welding, overlap welding, sealing welding, etc., with high aspect ratio, small welding seam width, and heat Small affected area, small deformation,

fast welding speed, smooth and beautiful welding seam, no treatment or simple treatment after welding, high welding seam quality, no porosity, precise control, small focus spot,

high positioning accuracy, easy to achieve Automation, the following content is mainly the analysis of the advantages of the metal sheet laser welding machine applied to the welding

of ultra-thin stainless steel materials.

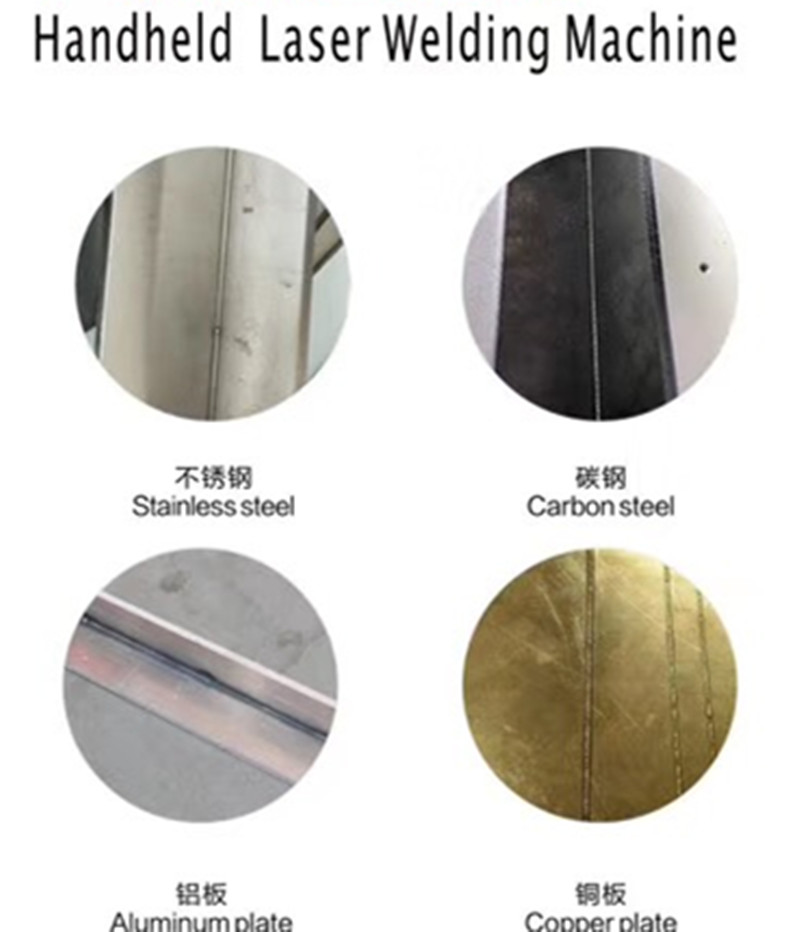

Stainless steel is widely used in various industries due to its good corrosion resistance, non-toxicity, friction resistance, high strength, non-magnetic, easy processing, good

weldability and other characteristics. In the sheet metal laser welding industry, there are many manufacturers that use sheet metal laser welding of stainless steel workpieces,

and stainless steel is also the best welded among many materials, and the effect is the best.

Advantages of sheet metal laser welding machine for welding ultra-thin stainless steel materials

Compared with the traditional welding, the low-power pulsed metal sheet laser seam welding has the advantages of high power density, energy concentration, small heat input,

narrow weld seam and small deformation, and the laser beam of the metal sheet can be very focused. The small spot can be precisely positioned. These characteristics make

the metal sheet laser seam welding more suitable for welding small-sized workpieces than other welding methods. For the laser welding of metal sheets of ultra-thin stainless

steel materials, because the material is very thin, it is easy to vaporize and perforate. In order to obtain a continuous, non-burn-through weld, the key is to accurately control the

parameters.

The main parameters that affect the quality of sheet metal laser welding are welding current, pulse width, pulse frequency, etc. The main effects are as follows:

- With the increase of the current, the width of the welding seam increases, and the welding process gradually shows splashes, and the surface of the welding seam appears

- oxidized and has a rough feeling.

- As the pulse width increases, the width of the weld is also increasing. The change of pulse width has a significant effect on the welding effect of the laser welding machine

- for stainless steel ultra-thin sheet metal sheet. A slight increase in the pulse width may cause the sample to be oxidized and burned through.

- As the pulse frequency increases, the overlap rate of solder joints increases, and the width of the welds increases first. Basically remain unchanged afterwards. Observed

- under a microscope, the weld is getting smoother and more beautiful. However, when the pulse frequency increases to a certain value, the welding process spatters severely, the weld becomes rough, and the upper and lower surfaces of the welded parts are oxidized.

- Laser welding of ultra-thin metal sheets is suitable for positive defocusing. Under the same defocusing amount, the weld surface obtained by laser welding of positive

- defocusing metal sheets is smoother and more beautiful than negative defocusing.

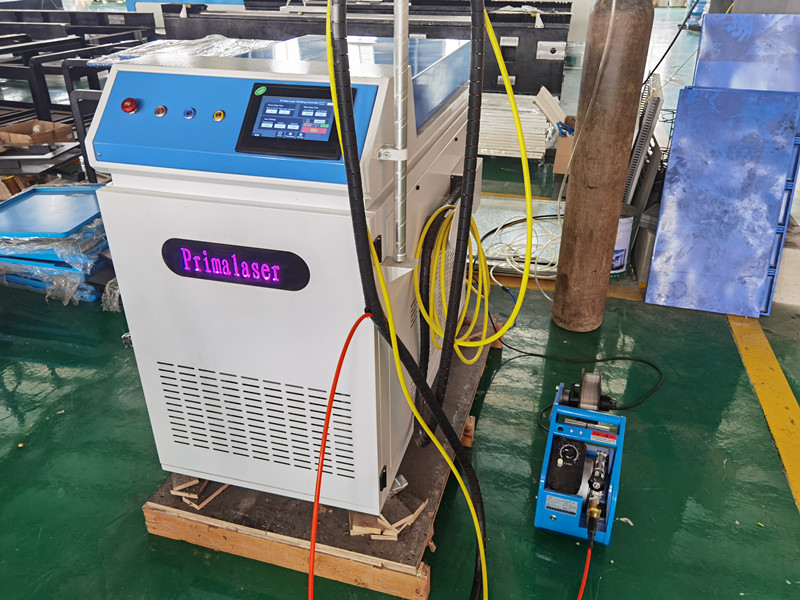

Advantages and application fields of hand-held sheet metal laser welding machine

Hand-held sheet metal laser welding machines are a good choice for many manufacturers in terms of portability and operation. The diversity of commodities gives us more choices.

Different commodities have different advantages. Hand-held sheet metal laser welding machines have higher production efficiency. For workshops engaged in small-scale

processing or non-large-scale welding, a handheld sheet metal laser welding machine is a better choice. The welding workbench can be deployed without setting equipment,

and it takes up little space. The focus is on diversified welding products and flexible product shapes. Metal sheet laser handheld welding machine can fully meet this demand.

The handheld sheet metal laser welding machine uses a handheld welding gun to replace the original fixed light path, which overturns the previous working mode of the

sheet metal laser welding machine. This operation method is not only convenient for welding molds, advertising slogans, kitchen utensils and other products,

but also suitable for outdoor metal sheet laser welding.