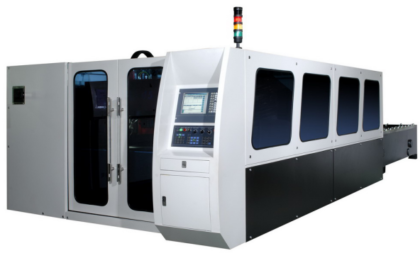

Winter Maintenance prima cnc Laser Cutting Machine Has Unique Skills

Precautions:

1. boot sequence

Since the laser cutting confidential work, laser cutting machine chassis could not be completely sealed, when the fiber laser cutting machine to complete the work day, night after power failure, the chassis air conditioning stopped, if the room does not have air-conditioning or air conditioning does not work at night, outside hot and humid air may gradually penetrate into the enclosure, the laser technicians recommend in premise of ensuring safety, laser night uninterruptible power, air conditioning to keep running so that the chassis or the laser cutting machine working in air-conditioned rooms, maintain the proper temperature.

2. ensure airtight enclosure

Fiber laser cutting machine uses a closed chassis design, chassis and install an air conditioner or a dehumidifier, its purpose is to ensure that all elements within the chassis at a relatively stable security environment of temperature and humidity. If the enclosure is not in the closed state, the hot and humid air from outside the enclosure can easily enter the inside of the chassis, in the face of internal water cooling elements at the surface freezes, possible damage, so make sure case closed.

3. Water temperature setting

Cooling water temperature has a direct influence on the electro-optical conversion efficiency, stability and condensation, so want to make a set temperature, the water temperature can be set according to the recommendation form.