Description

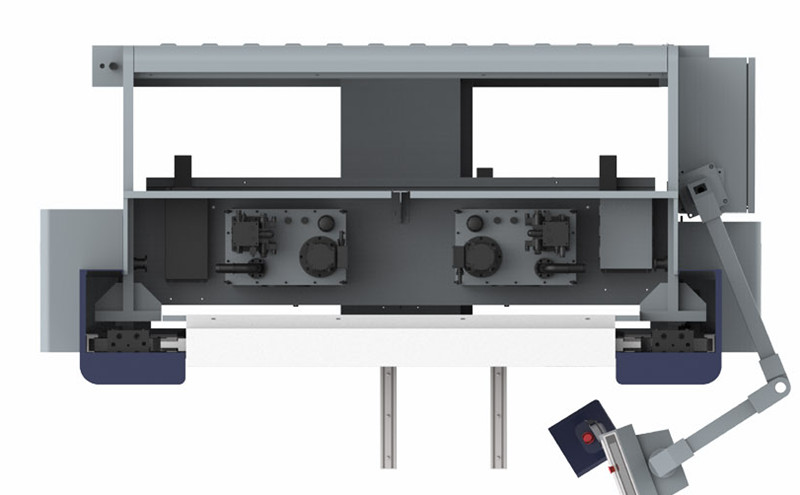

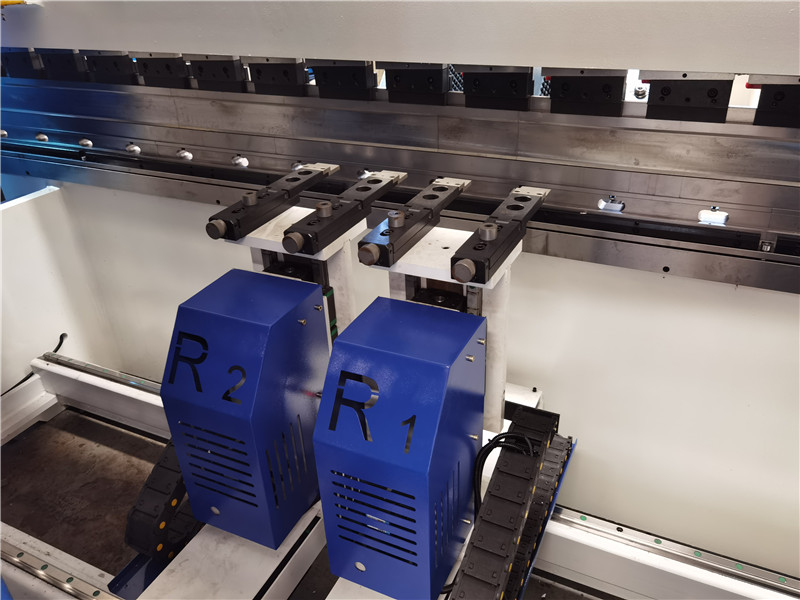

8+1 axis CNC Hydraulic Press Brake Delem DA69T CNC System with Y1 Y2 X1 X2 R1 R2 Z1 Z2 axis +V Crowning

Primapress cnc servo press brake features an CNC crowning system for improved quality, a servo driven back gauge system for increased speeds,

and 3D capable graphical control unit to simulate bending sequences and collision points.Also has increased working speeds, stroke, daylight,

and pressing capacities of GENIUS Series machines. The future – as a result of rising energy costs and increasingly cost efficient speed-controlled

drives offered on the market, variable-speed solutions are on the advance.

X: Backgauge front and back; Y1,Y2: Left and right oil cylinder stroke

R : Backgauge up and down; Z1,Z2: Left and right stopper movement

V: Worktable crowning

DA69T CNC Controller features:

* 3D and 2D graphical touch screen programming mode

* 3D visualisation in simulation and production

* 17″ high resolution colour TFT

* Full Windows application suite

* Delem Modusys compatibility (module scalability and adaptivity)

* USB, peripheral interfacing

* User specific application support within the controllers multitasking environment

* Sensor bending & correction interface

* Profile-T3D offline software

Main configuration

| Name | Producer |

| CNC controller | DA69T Delem Holland brand |

| Main motor | Siemens Germany brand |

| Electrical components | Schneider France brand |

| Gear pump | Sunny USA brand |

| Seal ring | NOK Japan brand |

| Hydraulic system | Boschrexroth Germany brand |

| Ball screw ,Linear guide | HIWIN Taiwan brand |

| Grating ruler | GIVI Italy brand |

| Tubing connector | EMB Germany Brand |

| Back guage servo motor and drive | Delta Taiwan Brand |

The standard accessories are in the below:

- Anchor bolt 2. Hex nut 3. Seal ring 4. Gasket 5. Grease gun

6. Allen wrench 7. Foot switch 8. Front support arms

9. Electrical box key, control panel key 10. Operation manuals

#brake press elettric #harsle press brake #press brake clamp

#promecam press brake tooling #durma press brake 200tx3200